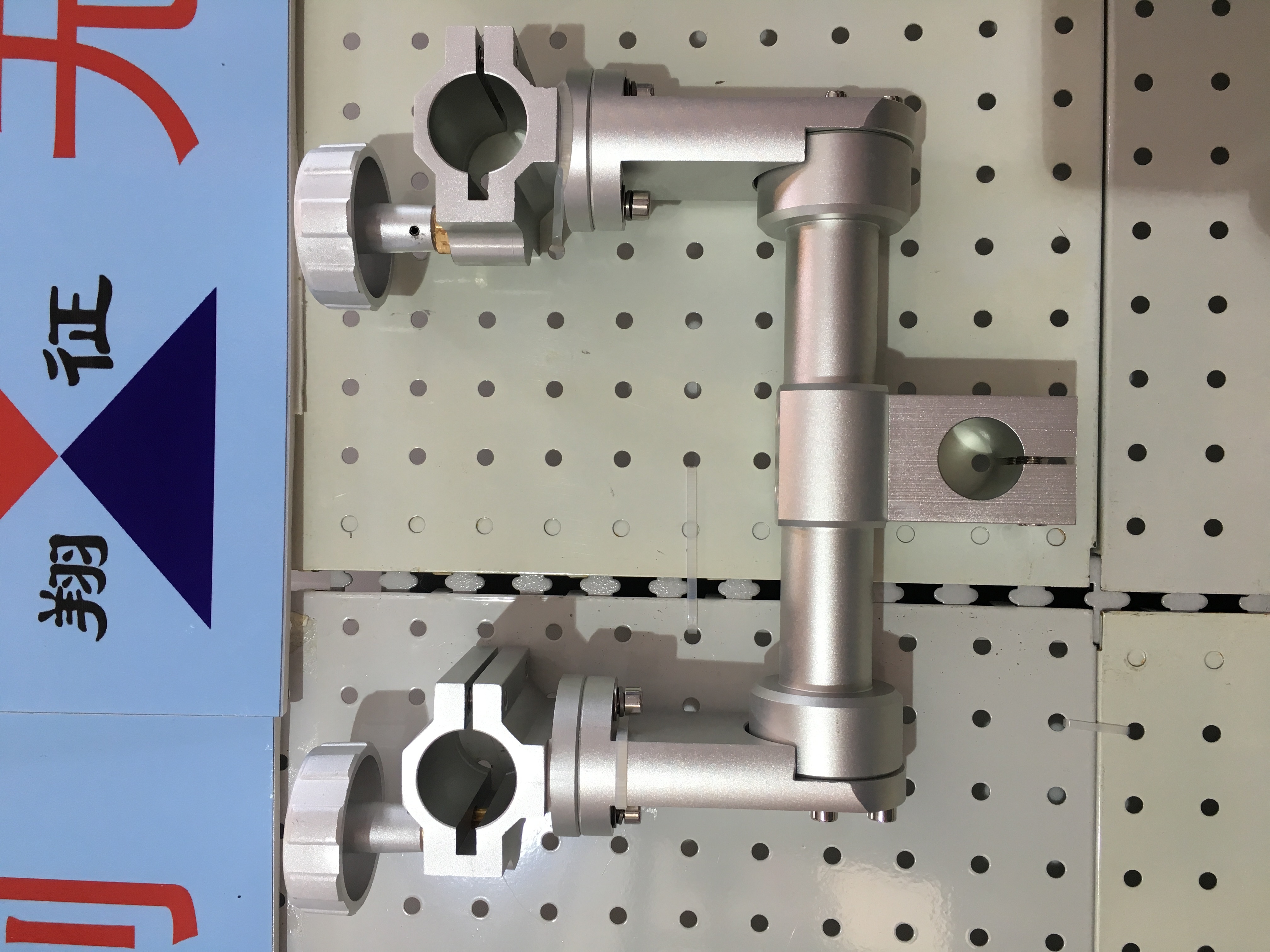

Double use holder for powder spraying marking

Double use holder for powder spraying marking Specification

- Material

- High-grade metal alloy

- Length

- Approx. 120 mm (as per image reference)

- Features

- Double use holder, robust construction, corrosion resistant

- Operate Method

- Manual operation with ergonomic grip

- Machine Type

- Compatible with manual as well as semi-automatic marking setups

- Coating

- Powder coated for enhanced durability

- Operation Type

- Dual-use operation with easy switching

- Hardness

- High wear resistance, value not specified

- Tool Type

- Holder for powder spraying marking

- Shape

- Cylindrical with dual holding mechanism

- Coating Type

- Powder spray

- Cutting Accuracy

- Suitable for precise marking applications

- Cutting Force

- Manual force, designed for ease of operation

- Diameter

- Approx. 30 mm (as per image reference)

- Processing Type

- Powder spraying and marking

- Weight

- Lightweight, approx. 200 g (as per standard makes)

- Grip Type

- Ergonomic, anti-slip

- Marking Compatibility

- Suitable for various powder marking powders

- Attachment Type

- Quick lock/unlock mechanism

- Color

- Typically metallic with powder finish

- Usage Area

- Industrial marking, construction, and manufacturing lines

- Temperature Resistance

- Tolerates typical powder coating curing temperatures

- Maintenance

- Easy to clean and maintain

- Package Contents

- 1 x Double use holder for powder spray marking

Double use holder for powder spraying marking Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30000 Pieces Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

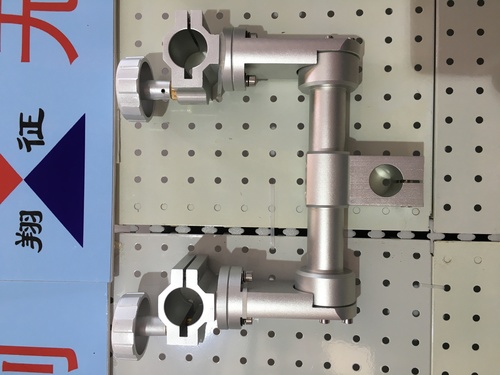

About Double use holder for powder spraying marking

This innovative Double use holder for powder spraying marking tool, enhance efficiency and accuracy. Its dual-purpose design accommodates two different powder colors or types, offering versatility for various marking applications. Crafted from durable materials, it ensures long-lasting performance and reliability in challenging environments. The holders ergonomic design reduces operator fatigue and improves overall productivity. With adjustable settings for powder flow and coverage, it provides precise control for achieving desired marking results. Upgrade your marking process with this advanced Double use holder for powder spraying marking.

Structural Features

- Compatible with flame cutting torches and powder spraying marking devices.

- Handwheel facilitates easy adjustment of lifting, lowering, and angle at joints.

- Durable construction ensures long-term reliability in industrial settings

- Ergonomic design for comfortable and efficient use.

- Versatile functionality for various cutting and marking applications

- Precision control for achieving accurate results.

- Enhances productivity and reduces operator fatigue.

- Suitable for use in challenging environments with adjustable settings for different tasks.

Ergonomic Design for Effortless Marking

With its anti-slip, ergonomic grip, the holder fits comfortably in hand, reducing operator fatigue during repetitive marking. The dual-use feature allows quick switching between powder types, supporting a more efficient workflow in industrial environments.

Built for Durability and Longevity

The holders powder-coated metallic surface resists corrosion and wear, preserving its appearance and functionality despite frequent use. High-grade metal alloy construction ensures it withstands harsh manufacturing conditions and maintains precise marking accuracy.

Easy Maintenance and Cleaning

Designed for convenience, the double use holder can be cleaned and maintained using common industrial cleaning practices. Its robust construction allows for repeated cleaning without degrading performance, supporting everyday operational reliability.

FAQs of Double use holder for powder spraying marking:

Q: How do I use the Double Use Holder for powder spraying marking?

A: To use the holder, attach the marking powder container with the quick lock/unlock mechanism, grip the ergonomic handle, and manually operate it to apply powder precisely. It supports dual-use switching for marking different powders.Q: What types of marking powders are compatible with this holder?

A: The holder is suitable for a variety of powder marking applications, allowing the use of most standard marking powders used in industrial, construction, and manufacturing processes.Q: Where is the Double Use Holder typically utilized?

A: This tool is ideal for industrial marking on manufacturing lines, construction sites, and areas requiring precise, durable powder-based markings. Its versatile design suits both manual and semi-automatic setups.Q: What is the maintenance process for this holder?

A: Cleaning is straightforwardwipe the surface and internal components using appropriate industrial cleaners. Routine inspections are recommended to keep the locking mechanism and grip in optimal condition.Q: What benefits does the double use dual holding mechanism offer?

A: The double use mechanism enables quick transitions between marking powders or methods, increasing operational flexibility and efficiency while reducing downtime during marking tasks.Q: Is the holder resistant to high temperatures encountered during powder coating?

A: Yes, it tolerates typical powder coating curing temperatures due to its robust powder-coated finish, preserving its structural integrity and appearance.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30000 Pieces Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Use Cutting Torch Holder Category

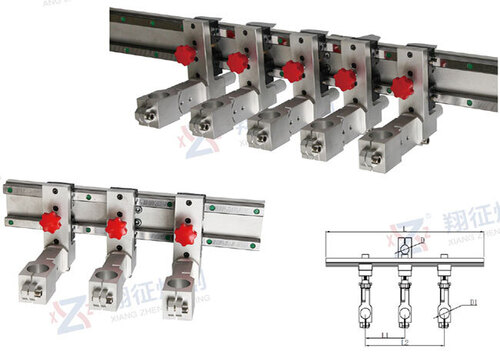

Machine Use Cutting Torch Holder

Minimum Order Quantity : 1000 Sets

Hardness : High Hardness Steel Body

Operation Type : Other, Automatic & Manual Adjustment

Cutting Force : Manual or Mechanically Assisted

Cutting Accuracy : Precision Aligned, 0.5 mm

Coating Type : Industrial Powder Coating

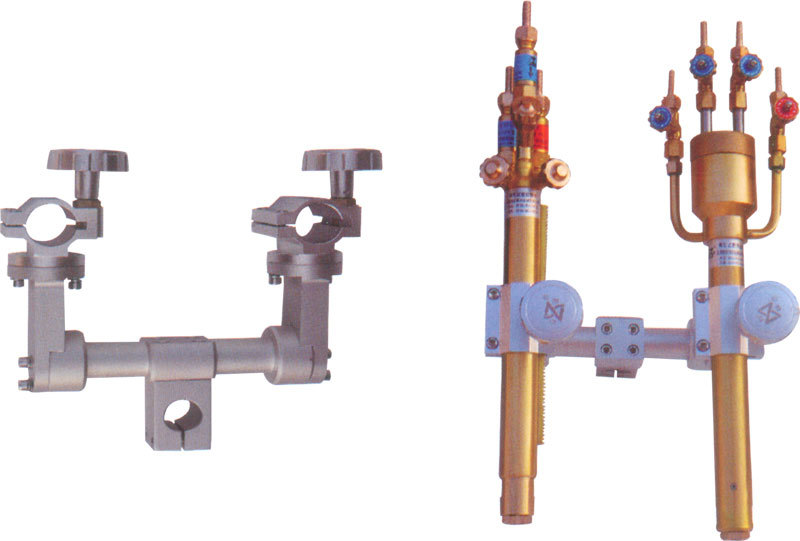

Follow up load bearing triple cutting torch holder

Minimum Order Quantity : 1 Set

Hardness : Robust Steel Construction

Operation Type : Other, Manual / Assisted

Cutting Force : Suitable for Heavy Duty Cutting

Cutting Accuracy : High Precision Alignment

Coating Type : Powder Coated / Painted

Small spacing and large thickness holder-five tips

Minimum Order Quantity : 1 Set

Hardness : High Hardness for Tough Applications

Operation Type : Other, Manual or Automatic (as per machine integration)

Cutting Force : High Cutting Force Suitable for Thick Materials

Cutting Accuracy : Precision Fit for Small Spacing Operations

Coating Type : Industrial Grade Coating

Anti Collision Plasma Holder

Minimum Order Quantity : 1 Set

Hardness : High

Operation Type : Other, Automatic/Manual

Cutting Force : High

Cutting Accuracy : High Precision

Coating Type : Surface Treated