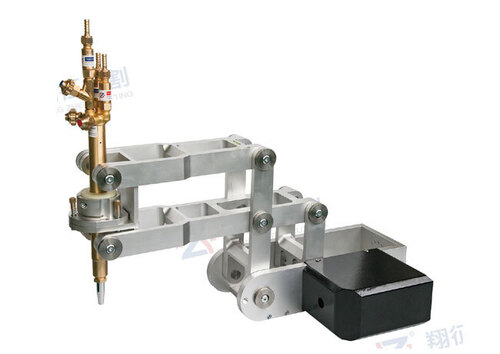

Follow up load bearing triple cutting torch holder

Follow up load bearing triple cutting torch holder Specification

- Cutting Force

- Suitable for Heavy Duty Cutting

- Shape

- Rectangular Base with Cylindrical Holders

- Machine Type

- Plasma & Oxy-Fuel Cutting Bridge/Track Machines

- Cutting Speed

- Depends on Torch (High Compatible Speed)

- Coating Type

- Powder Coated / Painted

- Hardness

- Robust Steel Construction

- Cutting Capacity

- Supports Three Torches Simultaneously

- Cutting Accuracy

- High Precision Alignment

- Tool Type

- Cutting Torch Holder

- Operate Method

- Follow-up Mechanism (Self Aligned Along Track)

- Features

- Follow-up Design, Load-Bearing, Adjustable Torch Clamps

- Cutter Type

- Triple Cutting Torch Holder

- Operation Type

- Manual / Assisted

- Length

- Approx. 350-400 mm

- Coating

- Protective Paint/Coating

- Material

- Heavy Duty Mild Steel / Alloy Steel

- Diameter

- Holder Tubes: Approx. 25-30 mm (Per Torch)

- Processing Type

- Fabricated

- Temperature Resistance

- Up to 600°C (Depending on Coating)

- Positioning Type

- Precision Guided

- Adjustment Range

- Adjustable Torch Spacing

- Number of Torches Supported

- 3

- Brand Compatibility

- Universal

- Usage Environment

- Heavy Industry, Fabrication Shops

- Surface Finish

- Anti-Rust

- Color

- Industrial Blue / Custom

- Weight Capacity

- Engineered for Heavy Load-Bearing

- Mounting Type

- Track / Bridge Mounted

- Application

- Industrial Plate Cutting

Follow up load bearing triple cutting torch holder Trade Information

- Minimum Order Quantity

- 1 Set

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Follow up load bearing triple cutting torch holder

Optimized Performance for Industrial Cutting Applications

The Follow Up Load Bearing Triple Cutting Torch Holder is designed for demanding usage scenarios. Ideal for heavy industry, fabrication shops, and large-scale plate cutting, it supports manual or assisted operation. Its precision-guided positioning enhances cutting accuracy, and the adjustable torch spacing accommodates various plate sizes and metals, making it suitable for a wide spectrum of application media and plant installations. Benefit from efficient, consistent results in heavy-duty settings with this adaptable cutting tool.

Sample Policy & Export Details

Our sample policy ensures proposal amount and sale price transparency for distributors, exporters, and traders. Samples can be provided on request, shipped swiftly via designated FOB ports in China. Main export markets include global heavy industry sectors, fabrication plants, and equipment suppliers. For each transaction, the shipped product arrives securely packaged, reflecting our commitment to prompt, reliable delivery and customer satisfaction. Competitive markdowns are available to support large-volume orders.

FAQ's of Follow up load bearing triple cutting torch holder:

Q: How does the triple cutting torch holder benefit industrial plate cutting operations?

A: It enhances efficiency by allowing simultaneous use of three torches, resulting in faster cutting and improved alignment across large plates. This increases productivity while maintaining precision in heavy-duty industrial settings.Q: What is the adjustment process for torch spacing on this holder?

A: The adjustable torch clamps let users manually set spacing between the three torches, accommodating various plate sizes and cutting requirements, ensuring optimal results for different operational needs.Q: When is the best usage environment for this torch holder?

A: It is ideally used in heavy industry fabrication shops and plants requiring high-capacity, load-bearing cutting tools and precise alignment, especially for plasma and oxy-fuel cutting machines.Q: Where can the torch holder be mounted in a plant setup?

A: This holder is designed for bridge or track mounting, ensuring self-aligned positioning along the cutting track, making it suitable for industrial cutting machines and fabrication lines.Q: What coating type is applied to support temperature-resistant usage?

A: The torch holder features protective powder-coated or painted finishes, providing robust anti-rust and temperature resistance up to 600C, depending on the selected coating.Q: How does the universal brand compatibility impact installation?

A: Its universal compatibility ensures it can be integrated seamlessly with various brands of cutting machines, reducing installation complexities and maximizing flexibility.

Price 1 USD ($)/ Set

- Minimum Order Quantity

- 1 Set

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Use Cutting Torch Holder Category

Intersection Line

Minimum Order Quantity : 1 Set

Operation Type : Other, Cross Section Cutting

Features : Rust Proof, Durable, High Strength

Material : Others, HighGrade Steel

Operate Method : Manual

Anti Collision Plasma Holder

Minimum Order Quantity : 1 Set

Operation Type : Other, Automatic/Manual

Features : Anticollision protection, Durable build, Stable performance

Material : Others, Durable Metal Alloy

Operate Method : Mountable on Torch

The triple cutting torch holder-two tips

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Operation Type : Cutting, Other

Features : Twotip design multiple holder mechanism

Material : Stainless Steel

Operate Method : Manual positioning

Moving body

Price 1.0 USD ($)

Minimum Order Quantity : 1

Operation Type : Linear, Other

Features : Adjustable mechanism with clamp

Material : Stainless Steel

Operate Method : Manual