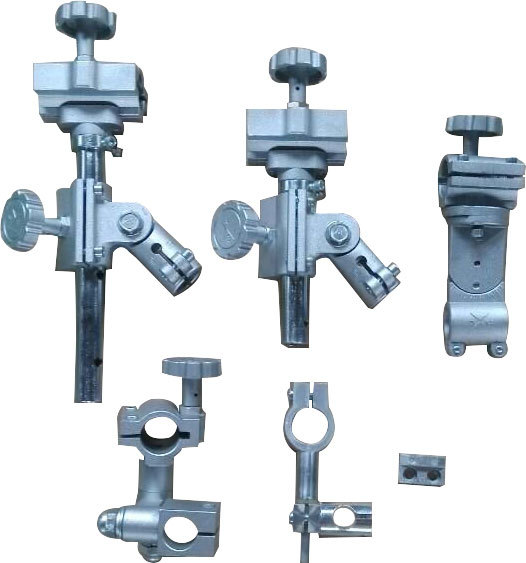

Machine Use Cutting Torch Holder

Machine Use Cutting Torch Holder Specification

- Material

- Hardened Alloy Steel, Heavy Duty Cast Iron Base

- Coating

- Rust Resistant Finish

- Features

- Firm torch grip, Easy adjustment, Rust proof, Heat resistant, Heavy duty, Precision guiding

- Coating Type

- Industrial Powder Coating

- Cutting Accuracy

- Precision Aligned, 0.5 mm

- Machine Type

- Pipe, Profile, and Plate Cutting Machine Compatible

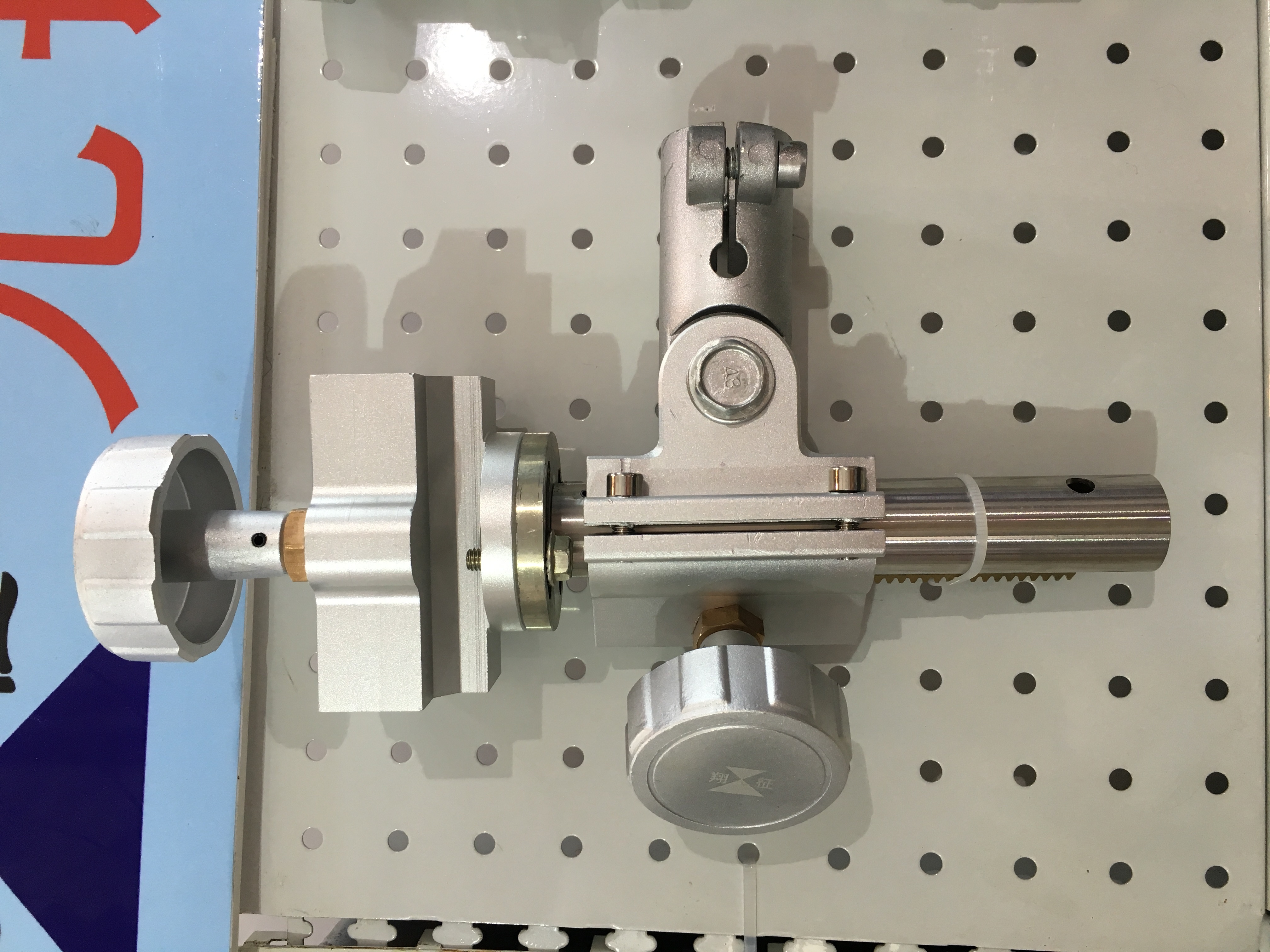

- Operation Type

- Automatic & Manual Adjustment

- Cutter Type

- Torch Flame Cutter Compatibility

- Hardness

- High Hardness Steel Body

- Length

- 260 mm (approximate)

- Cutting Capacity

- Suitable for Mild Steel & Stainless Steel Sheets Up to 100 mm Thickness

- Cutting Speed

- Adjustable, Dependent on Torch Type

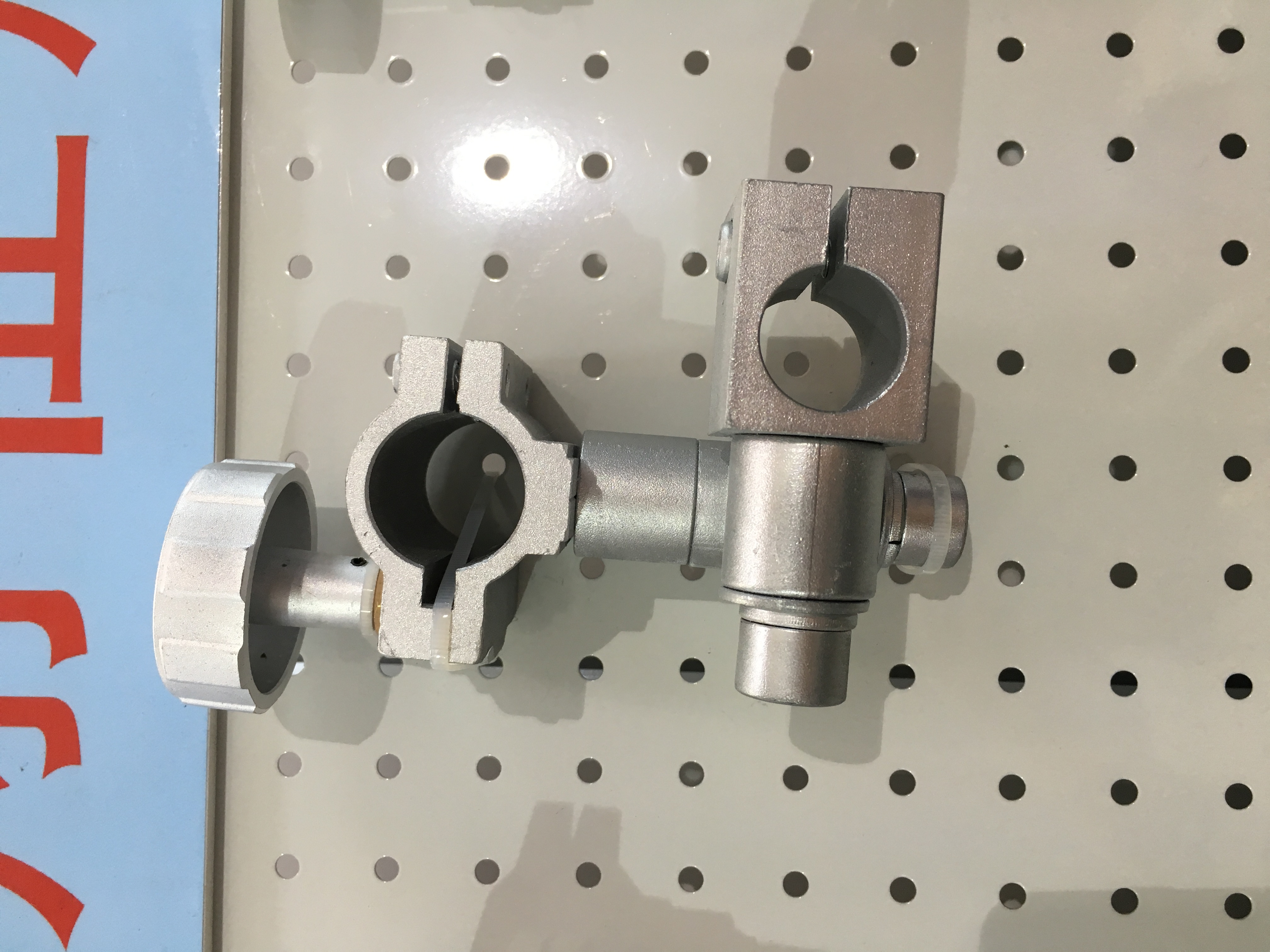

- Shape

- Round Clamp Holder

- Operate Method

- Mechanically Operated with Handwheel or Motor

- Tool Type

- Torch Holder for Cutting Machines

- Cutting Force

- Manual or Mechanically Assisted

- Diameter

- Compatible with 22 mm to 32 mm Torch Diameter

- Maximum Torque

- Up to 30 Nm

- Processing Type

- Thermal Cutting/Plasma Cutting/Oxy-Fuel Cutting

- Usage Application

- Automated or Semi-Automated Cutting on Pipes, Sheets, and Plates

- Blade Size

- Compatible with Standard Cutting Torch Nozzle Sizes

- Heat Resistance

- Withstands Up to 600°C

- Suitable Torch Type

- Oxy-Fuel, Plasma, LPG, and Acetylene Torches

- Maintenance

- Low-Maintenance, Easy Cleaning

- Accessories Included

- Clamping Screws, Mounting Hardware

- Mounting Arrangement

- Universal Slide, Adjustable Base, Bolt-On or Clamp-On Mounting

- Weight

- Approx. 1.8 kg

- Color/Finish

- Industrial Grey/Black Powder Coated

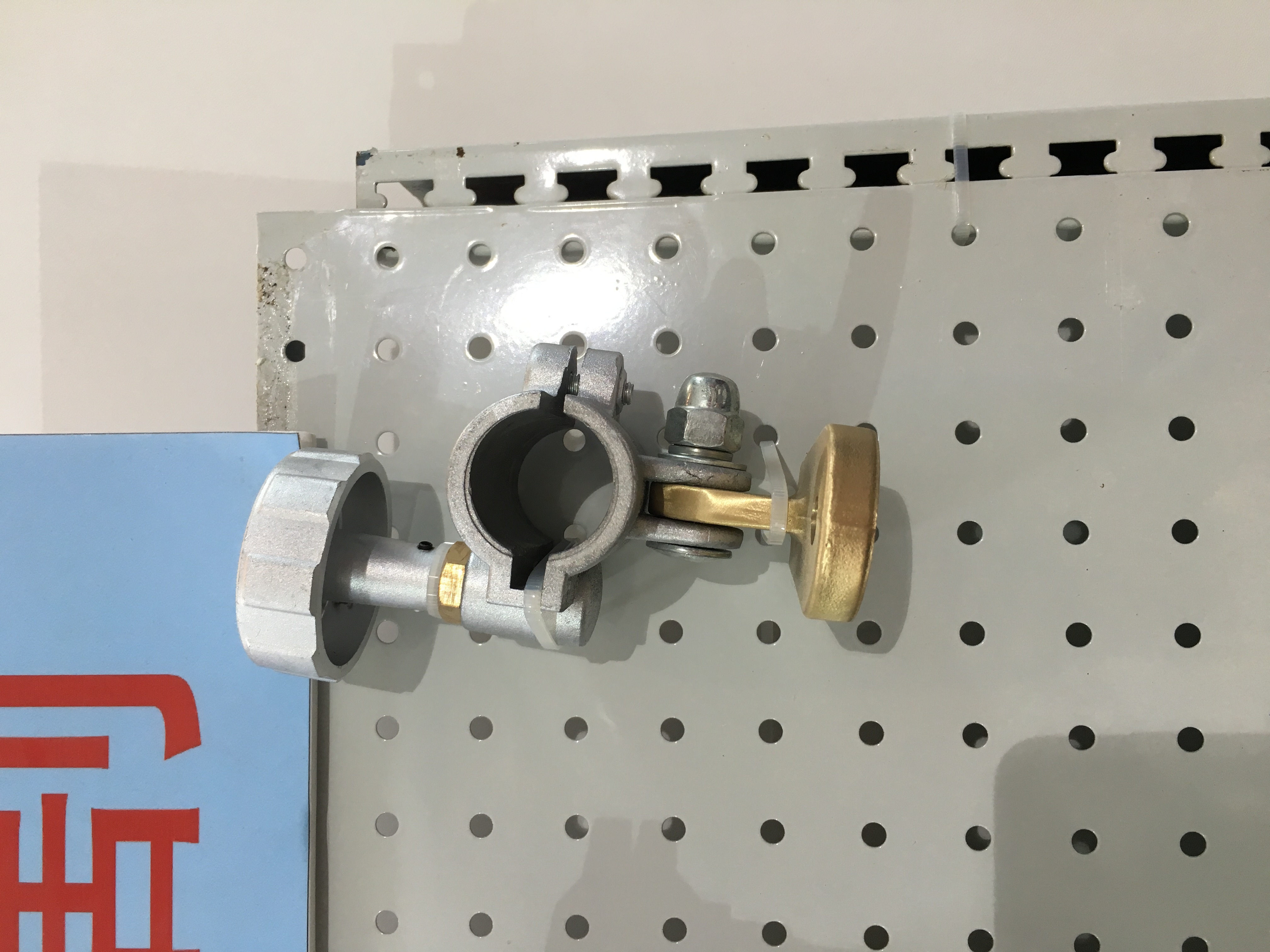

- Clamping Mechanism

- Quick Release Knob & Screw Tightening

Machine Use Cutting Torch Holder Trade Information

- Minimum Order Quantity

- 1000 Sets

- FOB Port

- Shanghai

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- standard export box or carton packing

- Main Export Market(s)

- South America, Eastern Europe, Middle East, Western Europe, North America, Central America, Australia, Asia, Africa

About Machine Use Cutting Torch Holder

It is accessories to connect the cutting torch and flame cutting machine.

Structural Features

- Applicable to machine-use cutting torch

- Using hand wheel to adjust rise and fall

- Using hand wheel to adjust horizontally moving distance

- Angle scale can show angle of the machine-use cutting torch.

Versatile Torch Compatibility

This torch holder accommodates various cutting torch types including Oxy-Fuel, Plasma, LPG, and Acetylene, supporting standard nozzle sizes. Its compatibility with different torches makes it a flexible solution for professional and industrial applications, ensuring precise and efficient performance on a range of materials.

Secure and Adjustable Clamping

Designed with both a quick release knob and screw tightening mechanism, the holder enables swift attachment and removal of your torch. The universal slide mounting and adjustable base allow for bolt-on or clamp-on installation, simplifying adjustment and ensuring firm, stable grip during operation.

Durable and Heat Resistant Design

Constructed from high-hardness steel and heavy-duty cast iron, the torch holder is finished with a rust-resistant industrial powder coat. It endures working temperatures up to 600C, making it ideal for heavy-duty automated or semi-automated cutting tasks in demanding shop and field environments.

FAQs of Machine Use Cutting Torch Holder:

Q: How do I mount the cutting torch holder onto my cutting machine?

A: The cutting torch holder features a universal slide mounting arrangement and an adjustable base, allowing for bolt-on or clamp-on installation. Simply secure the holder using the included clamping screws and mounting hardware, ensuring compatibility with torch diameters between 22 mm and 32 mm.Q: What types of cutting torches can be used with this holder?

A: This holder is compatible with Oxy-Fuel, Plasma, LPG, and Acetylene torches, making it suitable for various applications. It supports standard torch nozzle sizes and ensures precision guiding for multiple cutting processes like thermal, plasma, or oxy-fuel cutting.Q: When should I use this torch holder in my cutting operations?

A: This tool is ideal for automated or semi-automated cutting projects on pipes, sheets, and plates, especially when consistent accuracy and robust clamping are needed. Use it whenever you require reliable, repeatable cuts on mild steel or stainless steel up to 100 mm thick.Q: Where can this torch holder be used effectively?

A: It is suitable for workshops, industrial sites, and fabrication units. Its heat resistance and durable build make it effective for both stationary machine setups and mobile cutting operations on different materials and shapes.Q: What is the process for adjusting the torch position and cutting speed?

A: The holder provides automatic and manual adjustment options via handwheel or motor operation. Simply release the quick knob for rapid changes or fine-tune the position with the screw tightening system. Cutting speed adjustments depend on the chosen torch type for optimal results.Q: What are the benefits of choosing this cutting torch holder?

A: Key benefits include firm torch grip, precision-aligned accuracy within 0.5 mm, heat and rust resistance, low maintenance requirements, and compatibility with a wide array of torch types and applications. Its robust construction guarantees lasting performance and reduced downtime.

- Minimum Order Quantity

- 1000 Sets

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Main Export Market(s)

- South America, Eastern Europe, Middle East, Western Europe, North America, Central America, Australia, Asia, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Use Cutting Torch Holder Category

Follow up load bearing triple cutting torch holder

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Features : Followup Design, LoadBearing, Adjustable Torch Clamps

Material : Others, Heavy Duty Mild Steel / Alloy Steel

Operate Method : Followup Mechanism (Self Aligned Along Track)

Shape : Rectangular Base with Cylindrical Holders

Anti Collision Plasma Holder

Minimum Order Quantity : 1 Set

Features : Anticollision protection, Durable build, Stable performance

Material : Others, Durable Metal Alloy

Operate Method : Mountable on Torch

Shape : Round

Small spacing and large thickness holder

Minimum Order Quantity : 1 Set

Features : Supports small spacing, easy mounting, and high rigidity

Material : Others, Highgrade alloy steel

Operate Method : Manual

Shape : Rectangular holder with dual clamping slots

Anti Collision Plasma Holder-Fours holes position

Minimum Order Quantity : 1 Set

Features : Anticollision design, Four mounting holes for secure installation, Robust build

Material : Others, High Strength Steel/Aluminum Alloy

Operate Method : Fixed/Mounted

Shape : Rectangular with rounded corners and four mounting holes