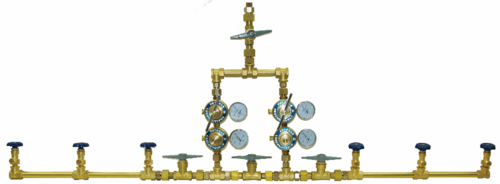

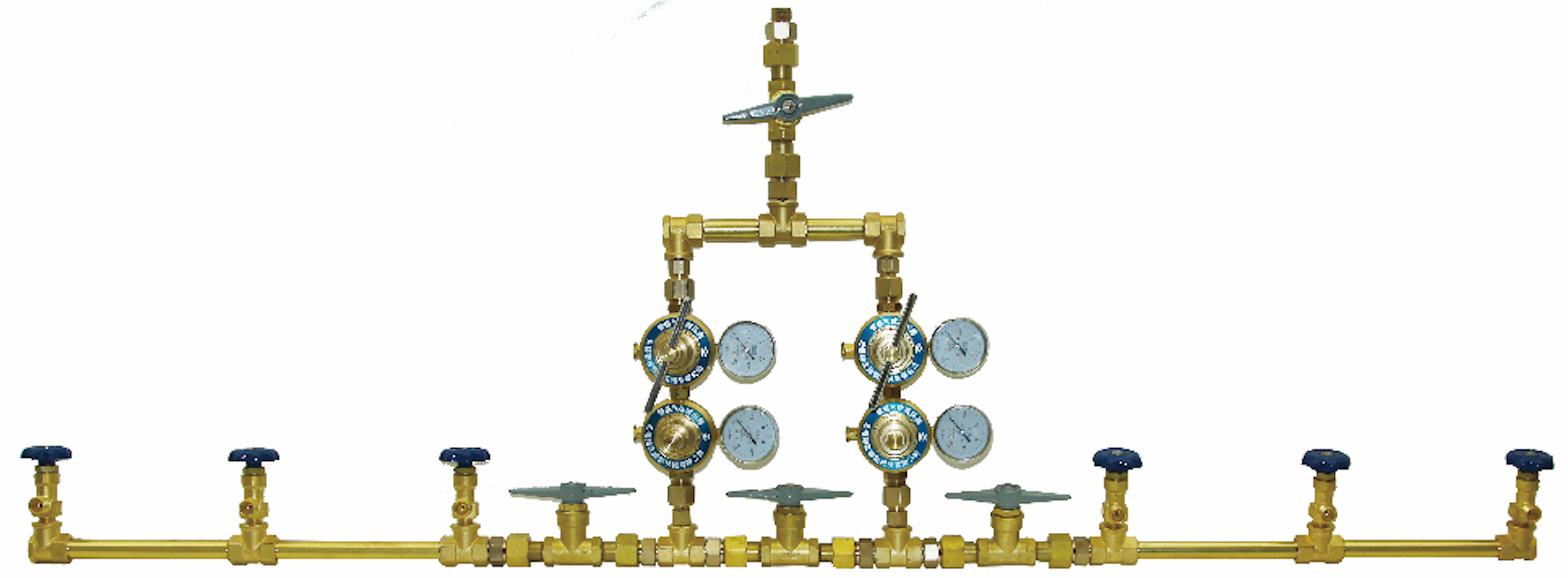

Double Side Cylinder Manifold

Double Side Cylinder Manifold Specification

- Material

- Stainless Steel

- Technique

- Forged

- Connection

- Threaded

- Shape

- Rectangular

- Head Code

- Round

- Type

- Cylinder Manifold

- Port Size

- 1/2 inch (customizable)

- Style

- Double Side

- Pressure

- Up to 350 Bar

- Application

- Gas Cylinder Distribution

- Leak Test

- Factory Tested

- Corrosion Resistance

- High

- Standards

- IS/BS/DIN (on request)

- Finish

- Polished

- Number of Stations

- 2 - 10 (as per requirement)

- Operating Temperature

- -20°C to 80°C

- Mounting

- Wall Mounted

- Inlet/Outlet Connection

- BSP/NPT Threaded

- Compatible Gases

- Oxygen, Nitrogen, Argon, etc.

Double Side Cylinder Manifold Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Double Side Cylinder Manifold

Structural Features:

- Dual-sided gas manifold design incorporates dual gas sources: main supply cylinder group and backup cylinder group.

- When main gas supply cylinder group pressure drops, close main gas supply valve and open backup gas cylinder group valve for uninterrupted gas supply.

- Manual operation of this busbar enables switching between main and backup gas sources, preventing gas supply interruptions.

Standard Configuration:

- High pressure hoses are metal hoses

- Flashback arrestor at the outlet of the acetylene and propane cylinder manifold.

- For use of acetylene and propane cylinder manifold, the connecting cylinder rack, T-shaped wrench and adaptor are fitted at the outlet end of the acetylene and propane cylinders.

- Adopting pressure reducer with large flow.

| Model No | Gas Service | Maximum input pressure | Output pressure | Maximum output flow | Outlet Connection |

| XZ-HLP | Oxygen | 15 | 0.071.4 | 100 | G5/8/G3/4-RH/M |

| XZ-HLP | Acetylene | 3 | 0.010.1 | 20 | M27x1.5-RH/M |

| XZ-HLP | Propane | 3 | 0.030.85 | 30 | M27x1.5-RH/M |

High Performance and Reliability

Each Double Side Cylinder Manifold undergoes strict factory leak testing to guarantee high safety and reliable operation. Its forged stainless steel construction and corrosion-resistant design make it ideal for demanding environments, providing longevity and consistent performance in gas distribution systems.

Versatile and Customizable Solutions

Available with 2 to 10 gas cylinder stations and customizable port sizes, manifolds are tailored to your precise requirements. Wall mounting, BSP/NPT threaded connections, and compatibility with key industrial gases ensure optimal integration into your worksite while meeting global standards for quality and safety.

Application and Industry Use

Designed for efficient gas cylinder distribution, the manifold is widely employed in laboratories, hospitals, and industrial facilities. Its polished finish and robust design make it fit for both clean and rugged environments, ensuring safe gas handling for a variety of technical processes.

FAQs of Double Side Cylinder Manifold:

Q: How do I install the Double Side Cylinder Manifold?

A: The manifold is designed for hassle-free wall mounting. Simply fix it securely on a sturdy wall surface using appropriate hardware, ensuring the connections match your inlet/outlet requirements (BSP or NPT threaded). Professional installation is recommended to guarantee safety and system integrity.Q: What gases are compatible with this cylinder manifold?

A: The manifold is compatible with a broad range of gases including Oxygen, Nitrogen, Argon, and other industrial gases, making it suitable for diverse applications such as hospitals, laboratories, and manufacturing plants.Q: When should I opt for a customizable port size or number of stations?

A: Customization is ideal when your application requires specific flow rates or the distribution of gas to more or fewer cylinders. The manifold can be tailored with 2 to 10 stations and a port size of 1/2 inch or as needed for your system specifications.Q: Where can this manifold be used effectively?

A: This manifold excels in environments requiring reliable gas distribution, such as industrial facilities, research labs, and healthcare settings. Its high corrosion resistance and wide operating temperature range make it adaptable to various locations and conditions.Q: What is the process for leak testing the manifold?

A: Every manifold undergoes rigorous factory leak tests before shipment. This ensures all connections and welded points uphold pressure integrity up to 350 Bar, providing peace of mind for safety-critical applications.Q: How does using a double side design benefit gas distribution?

A: The double side design allows for easier access and streamlined control of multiple gas cylinders, maximizing efficiency and reducing downtime during cylinder changeovers or maintenance.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

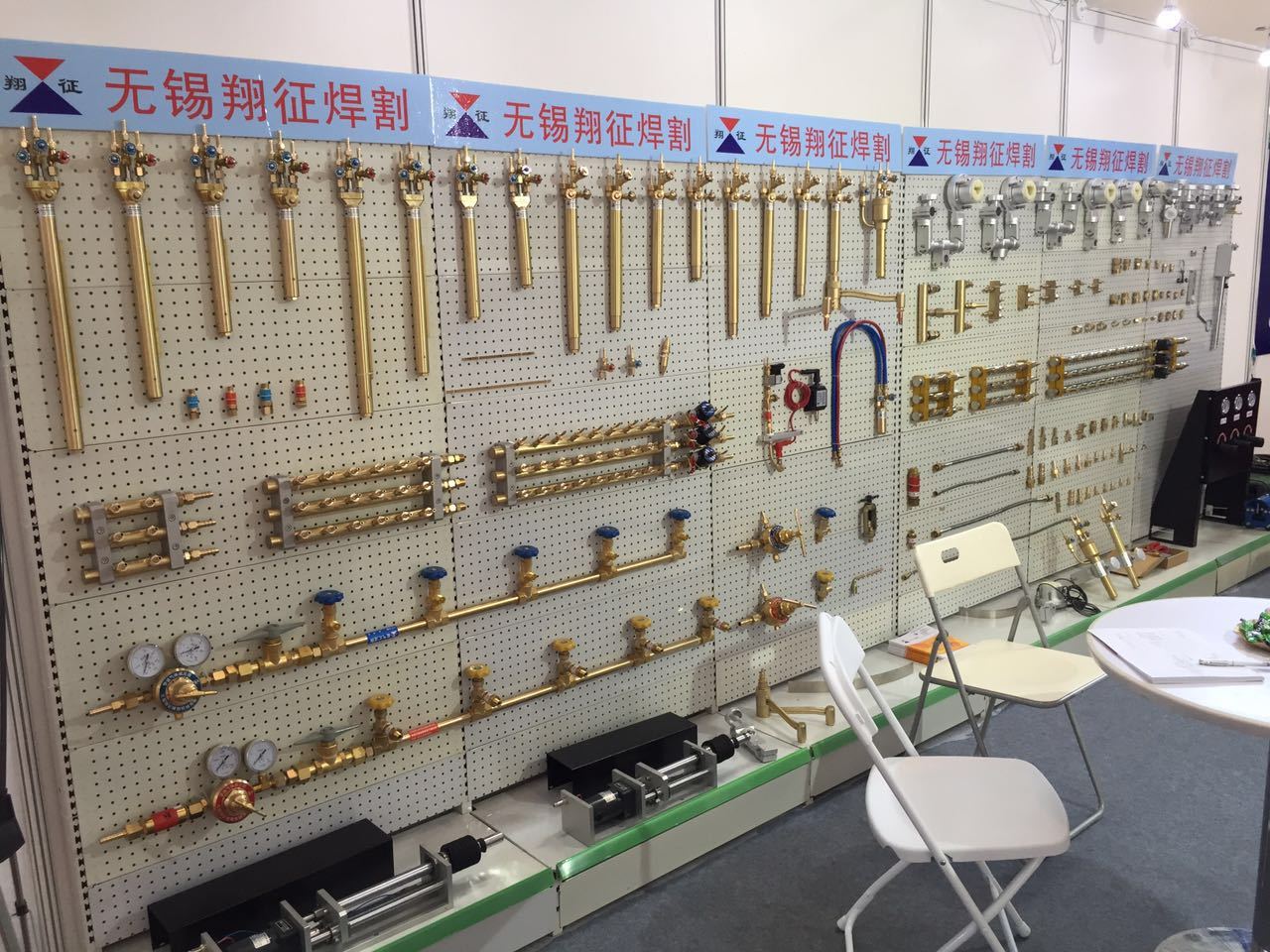

More Products in Cylinder Manifold Category

Gas Regulator

Minimum Order Quantity : 1 Set

Style : Manual

Port Size : 1/4 Inch

Shape : Other, Cylindrical

Head Code : Other, Round

Application : Gas Cylinder Regulator

Single Side Cylinder Manifold

Minimum Order Quantity : 1 Set

Style : Single Side

Port Size : 1/4 inch, 1/2 inch, 3/4 inch (customizable)

Shape : Other, Rectangular Block (with cylindrical ports)

Head Code : Hexagon

Application : Industrial Gas Distribution, Medical Gas Supply

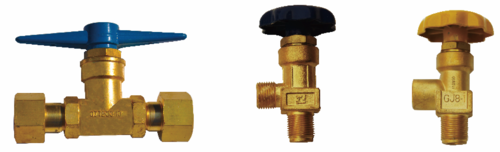

Gas Distribution Pipeline Valve

Minimum Order Quantity : 1 Set

Style : Industrial

Port Size : 1/2 Inch

Shape : Other, Straight

Head Code : Other, Round

Application : Gas Distribution Pipeline

High Pressure Metallic Hose

Minimum Order Quantity : 1 , , Set

Style : Corrugated

Port Size : 1/4 to 12 (inches)

Shape : Other, Round

Head Code : Other, Round

Application : Steam, Gas, Oil, Chemical, Water, Air Conveyance