High Pressure Metallic Hose

High Pressure Metallic Hose Specification

- Material

- Stainless Steel (SS 304/316)

- Technique

- Seamless/Welded with Braiding

- Connection

- Flanged, Threaded, Welded

- Shape

- Round

- Head Code

- Round

- Type

- Flexible Metallic Hose

- Port Size

- 1/4 to 12 (inches)

- Style

- Corrugated

- Pressure

- Up to 300 bar (High Pressure)

- Application

- Steam, Gas, Oil, Chemical, Water, Air Conveyance

- Inner Diameter

- 6 mm to 300 mm

- Leak Test

- 100% Hydrostatic Leak Tested

- Burst Pressure

- 4 times of Working Pressure

- End Fittings

- Flange, Union, Nipple, or as per requirement

- Corrosion Resistance

- Excellent

- Lining

- Stainless Steel Corrugated

- Hose Construction

- Single or Double SS Braided

- Length

- Up to 30 meters (Customizable)

- Temperature Range

- -200°C to +600°C

- Bend Radius

- As per DIN/ISO Standard

High Pressure Metallic Hose Trade Information

- Minimum Order Quantity

- 1 , , Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 10-15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

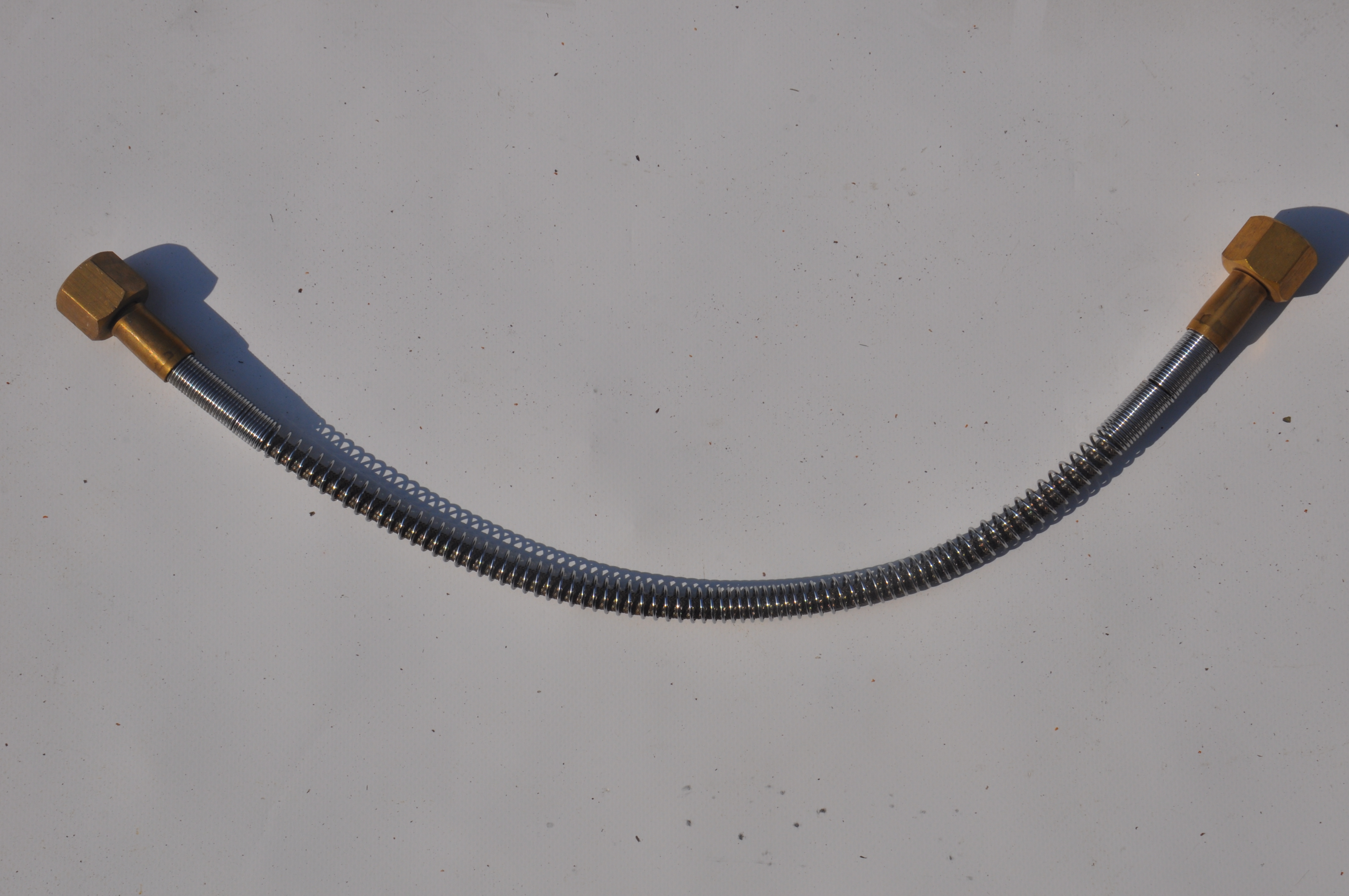

About High Pressure Metallic Hose

Do you want to buy High Pressure Metallic Hose? If yes, than checkout our product which is formed up of high grade brass and stainless steel with the Ptfe lining. It is annular braids added to install in metal hose which significantly improve the pressure require in the industries tanks and silos. The hose is capable of withstanding extraordinarily high temperature and pressure applications, such as hydraulic systems. It is offered in the 500mm to 1000mm dimension with seamless finishing quality. The High Pressure Metallic Hose is durable for longer period of time and require minimal maintenance service.

Connect the gas manifold with the cylinder.

| Model NO | Gas Service | Inlet/outlet Connection | Length | Type |

| LJGX105 | Oxygen | G5/8-RH /F | 500mm/1000mm | Metallic Hose(Lining:Ptfe) |

| LJGY105 | Acetylene | M16x1.5-RH/F | 500mm/1000mm | Metallic Hose(Lining:Ptfe) |

Exceptional Durability for Demanding Applications

This high pressure metallic hose is manufactured from stainless steel (SS 304/316) and is meticulously designed for longevity, even in the harshest chemical, thermal, or mechanical environments. Its seamless or welded construction, along with single or double braiding, delivers outstanding pressure control while maintaining flexibility.

Customizable to Suit Your Process Needs

With sizes ranging from 6 mm to 300 mm inner diameter and lengths up to 30 meters, these hoses can be tailored to your application. Various end fittingsflanged, threaded, or weldedensure compatibility with diverse setups, making them well suited for distributors, exporters, suppliers, and manufacturers handling a wide variety of fluids and gases.

FAQs of High Pressure Metallic Hose:

Q: How does the high pressure metallic hose perform under extreme temperatures?

A: The hose is designed for outstanding performance from -200C to +600C, making it suitable for both cryogenic and high-temperature applications without compromising flexibility or safety.Q: What makes the hose suitable for handling corrosive or hazardous materials?

A: The use of stainless steel (SS 304/316) ensures excellent corrosion resistance, making the hose ideal for transporting chemicals, steam, oil, and other aggressive substances safely.Q: When should I opt for single versus double braided construction?

A: Single-braided hoses are chosen for moderate-pressure environments, while double-braided hoses provide reinforced strength and are preferred for high pressure (up to 300 bar) or dynamic installations requiring additional safety.Q: Where can the high pressure metallic hose be installed?

A: These hoses are adaptable for installation in industrial plants, chemical processing units, oil & gas facilities, and utilities, wherever flexible connections are required between pipelines, machinery, or storage tanks.Q: What is the process for hydrostatic leak testing, and why is it important?

A: Each hose undergoes 100% hydrostatic leak testing, where water pressure is applied up to or beyond working levels to verify integrity, ensuring zero leaks, and enhancing operational safety.Q: How customizable are the length and fittings of the hose?

A: The hose can be manufactured in lengths up to 30 meters and fitted with a variety of end connections, including flange, union, nipple, or as per your bespoke requirements, ensuring optimal compatibility.Q: What are the primary benefits of using a corrugated metallic hose in industrial applications?

A: Corrugated metallic hoses provide outstanding flexibility, vibration absorption, and pressure containment, effectively handling mechanical movements and thermal expansion while maintaining system integrity.

- Minimum Order Quantity

- 1 , , Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 10-15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylinder Manifold Category

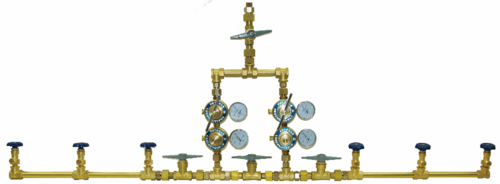

Double Side Cylinder Manifold

Minimum Order Quantity : 1 Set

Head Code : Other, Round

Technique : Forged

Shape : Other, Rectangular

Type : Cylinder Manifold

Port Size : 1/2 inch (customizable)

Gas Regulator

Minimum Order Quantity : 1 Set

Head Code : Other, Round

Technique : Other, Machined

Shape : Other, Cylindrical

Type : Single Stage

Port Size : 1/4 Inch

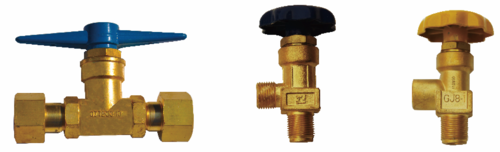

Gas Distribution Pipeline Valve

Minimum Order Quantity : 1 Set

Head Code : Other, Round

Technique : Forged

Shape : Other, Straight

Type : Pipeline Valve

Port Size : 1/2 Inch

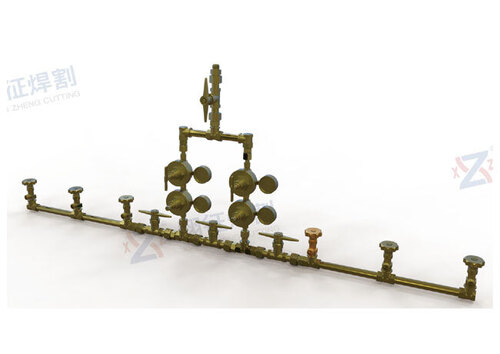

Double-Side Cylinder Manifold

Minimum Order Quantity : 1 Set

Head Code : Hexagon

Technique : Other, Precision Machined

Shape : Other, Rectangular Block with Dual Rows

Type : Gas Cylinder Manifold

Port Size : 1/4 inch BSP