Single Side Cylinder Manifold

Single Side Cylinder Manifold Specification

- Material

- Stainless Steel

- Technique

- Machined

- Connection

- Threaded / Flanged

- Shape

- Rectangular Block (with cylindrical ports)

- Head Code

- Hexagon

- Type

- Cylinder Manifold

- Port Size

- 1/4 inch, 1/2 inch, 3/4 inch (customizable)

- Style

- Single Side

- Pressure

- Up to 3000 PSI (customizable on request)

- Application

- Industrial Gas Distribution, Medical Gas Supply

- End Connection

- BSP/NPT threads or as required

- Compatible Gases

- Oxygen, Nitrogen, Argon, CO2, N2O, Air, Hydrogen

- Standards

- Conforms to IS/BS/ASTM standards

- Customization

- Available for port sizes, materials, and number of cylinders

- Weight

- Depends on Manifold Size (typically 3-10 kg)

- Mounting Type

- Wall Mounted or Frame Mounted

- Corrosion Resistance

- High

- Leak Test

- 100% Factory Tested

- Working Temperature Range

- -20°C to +80°C

- Surface Finish

- Polished

- Number of Outlets

- Customizable (typically 2 to 10)

Single Side Cylinder Manifold Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

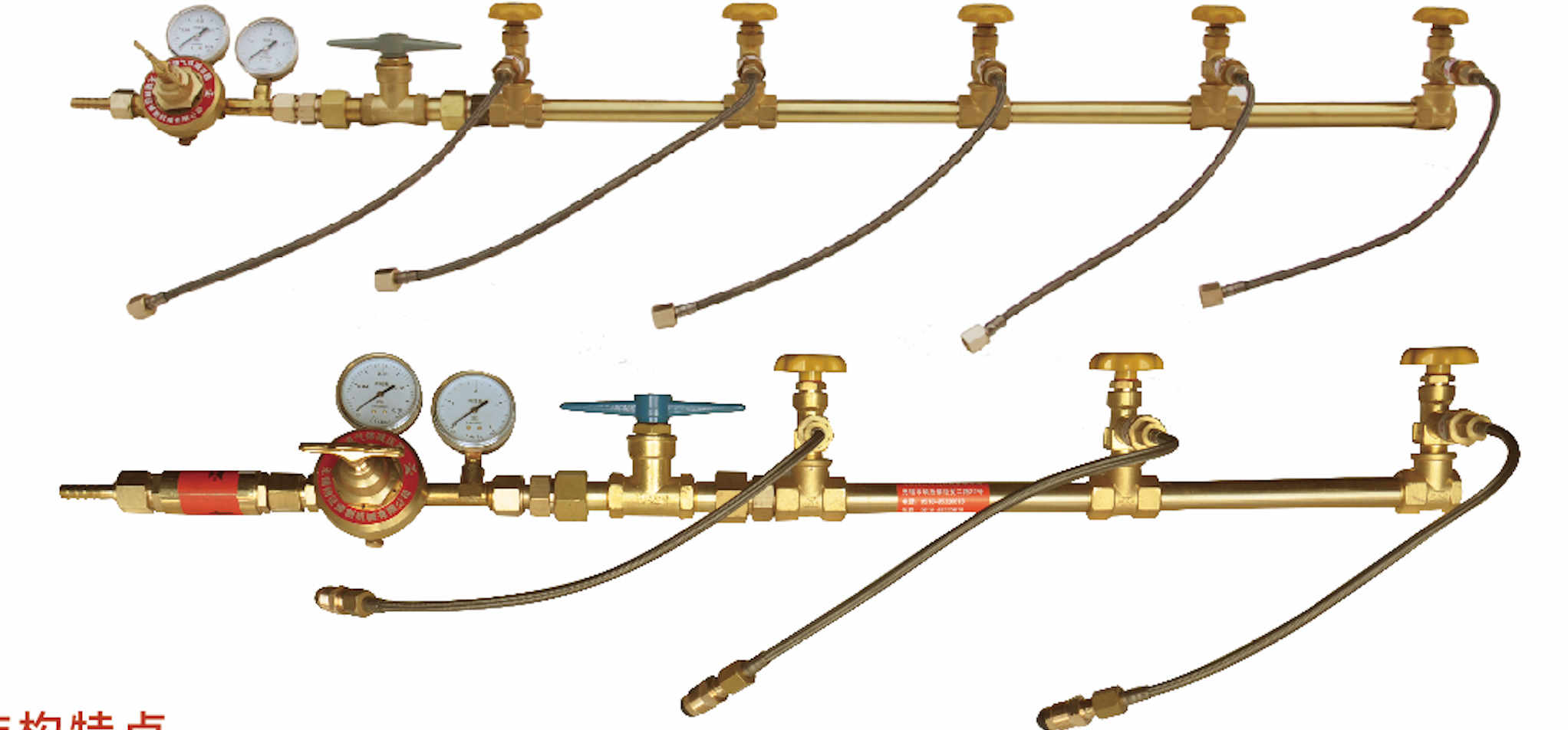

About Single Side Cylinder Manifold

The Single Side Cylinder Manifold is specially designed for use of single gas source, and can be widely used as a standby system for the main gas source or other gas sources like gas tank. They provide different gas services that include oxygen, acetylene and propane with excellent input pressure. Moreover, Single Side Cylinder Manifold is available in different series and model no as per requirement of the customers. The manifold is fabricated in our modern machines by using top notch brass metal under set standard industry rules and guidance.

Structural Features:

- Open structure design for enhanced accessibility and maintenance ease.

- Utilization of blind plugs at pipeline ends for expansion requirements.

- System has undergone rigorous withstand voltage testing, ensuring safety and reliability.

- Installation options include against-the-wall or horizontal placement.

- High-pressure hose incorporates a metal flexible conduit for durability and flexibility.

- Features a super large flow pressure regulator for optimal performance.

Standard Configuration:

- For use of acetylene and propane cylinder manifold, the connecting cylinder rack, T-shaped wrench and adaptor are fitted at the outlet end of the acetylene and propane cylinders.

- Adopting pressure reducer with large flow.

- High pressure hoses are metal hoses

- Flashback arrestor at the outlet of the acetylene and propane cylinder manifold.

| Model No | Gas Service | Maximum input pressure | Output pressure | Maximum output flow | Outlet Connection |

| XZ-HLP | Oxygen | 15 | 0.071.4 | 100 | G5/8/G3/4-RH/M |

| XZ-HLP | Acetylene | 3 | 0.010.1 | 20 | M27x1.5-RH/M |

| XZ-HLP | Propane | 3 | 0.030.85 | 30 | M27x1.5-RH/M |

Flexible Engineering for Diverse Demands

This manifold is engineered for versatility, allowing you to customize the number of outlets, port sizes, and even cylinder connections. Whether you need a compact solution for a medical facility or a robust system for industrial gas distribution, the product adapts to your requirements without sacrificing performance.

Built to Withstand Challenging Environments

Constructed from corrosion-resistant stainless steel and finished with a polished surface, the manifold maintains durability even in harsh conditions. It is leak tested up to 3000 PSI and ensures safe, continuous operation in temperatures ranging from -20C to +80C, making it suitable for a variety of climates and workspaces.

Certified Quality, Global Reach

Every manifold conforms to recognized IS/BS/ASTM standards, guaranteeing reliability and international compatibility. As a prominent distributor, exporter, manufacturer, supplier, and trader in China, we deliver products trusted by professionals worldwide for critical applications in both the industrial and medical sectors.

FAQs of Single Side Cylinder Manifold:

Q: How can the number of outlets on the cylinder manifold be customized?

A: The manifold is available with a customizable number of outlets, typically ranging from 2 to 10. Upon request, we can adjust the configuration to match your precise application needs, ensuring optimal gas distribution and system compatibility.Q: What types of gases are compatible with this manifold?

A: This manifold supports a variety of gases including Oxygen, Nitrogen, Argon, CO2, Nitrous Oxide (N2O), Air, and Hydrogen. It is designed for safe usage in both medical and industrial environments, adhering to stringent quality and safety standards.Q: When should I consider using a single side cylinder manifold in my facility?

A: You should opt for a single side cylinder manifold when you require organized and simultaneous distribution of gases from multiple cylinders. It is especially beneficial in installations where efficient space usage, centralized control, and high reliability are critical.Q: Where can the manifold be mounted for optimal performance?

A: The manifold can be mounted either on a wall or a dedicated frame, depending on your facility layout and operational needs. Its robust construction and flexible mounting options make it suitable for a wide range of locations, including industrial plants and healthcare settings.Q: What is the process for ensuring leak-free manifold operation?

A: Each manifold undergoes rigorous factory leak testing to guarantee 100% seal integrity at the specified operating pressures. This ensures that the manifold is safe and ready for installation upon delivery, reducing the risk of gas leaks and operational downtime.Q: How does the products corrosion resistance benefit long-term usage?

A: With its high-quality, corrosion-resistant stainless steel construction and polished finish, the manifold is protected against chemical and environmental deterioration. This not only extends service life but also increases safety and reduces maintenance costs in demanding operational environments.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylinder Manifold Category

Gas Regulator

Minimum Order Quantity : 1 Set

Material : Other, Brass

Port Size : 1/4 Inch

Connection : Other, Threaded

Shape : Other, Cylindrical

Head Code : Other, Round

High Pressure Metallic Hose

Minimum Order Quantity : 1 , , Set

Material : Other, Stainless Steel (SS 304/316)

Port Size : 1/4 to 12 (inches)

Connection : Other, Flanged, Threaded, Welded

Shape : Other, Round

Head Code : Other, Round

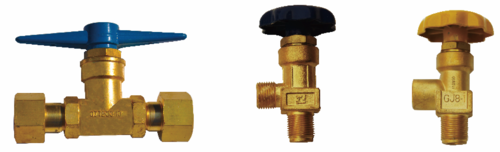

Gas Distribution Pipeline Valve

Minimum Order Quantity : 1 Set

Material : Other, Brass

Port Size : 1/2 Inch

Connection : Other, Threaded

Shape : Other, Straight

Head Code : Other, Round

Propane Cylinder Manifold

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Port Size : 1/4 inch NPT (customizable)

Connection : Other, Threaded/Flanged

Shape : Other, Rectangular

Head Code : Square