CLAMPS in rail

CLAMPS in rail Specification

- Length

- 120 mm (approx)

- Hardness

- HRC 38-42

- Tool Type

- Rail Clamp

- Features

- Corrosion Resistance, Easy Installation, High Strength

- Machine Type

- Rail Mounting Assembly

- Coating

- Anti-Rust Coating

- Operation Type

- Manual

- Coating Type

- Zinc Plated

- Shape

- Rectangular/Flat

- Material

- Forged Carbon Steel

- Operate Method

- Mechanical Fastening

- Processing Type

- Pressed/Stamped Metal

- Weight

- 650 grams (approx)

- Application

- Securing rail tracks to sleepers

- Packaging Type

- Bag/Box

- Temperature Resistance

- Up to 250°C

- Color

- Silver Grey

- Surface Finish

- Polished / Galvanized

- Tensile Strength

- High Tensile

- Maintenance

- Low maintenance required

- Usage

- Outdoor, Railway Infrastructure

- Standards

- Complies with IS and DIN railway standards

CLAMPS in rail Trade Information

- Minimum Order Quantity

- 1 Set

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About CLAMPS in rail

Versatile Applications of Rail Clamps

Our CLAMPS in rail excel in railway infrastructure projects. Specifically used for securely fastening rail tracks to sleepers, these clamps play a vital part in ensuring track stability and safety. Their design allows easy manual operation and mechanical fastening for rail mounting assemblies. Widely seen in outdoor railway works and construction zones, they stand out for their reliable grip and sublime anti-corrosive finish, making them a preferred choice for demanding application places.

Export Markets, Terms, and Offers for Rail Clamps

We proudly cater to various domestic and international markets, offering our superb rail clamps globally. Whether you are in the domestic mar or a leading export market, we provide flexible FOB Port options from China and customized packaging for bag or box dispatch. Take advantage of our attractive offers with convenient payment terms, making us your reliable distributor, exporter, manufacturer, supplier, and trader of rail clamps.

FAQ's of CLAMPS in rail:

Q: How are these rail clamps typically used in railway infrastructure?

A: These rail clamps are primarily used to secure rail tracks to sleepers, ensuring stability and safety in both construction and maintenance of railway lines.Q: What benefits does the polished, galvanized finish provide?

A: The polished or galvanized finish, complemented by an anti-rust coating, enhances corrosion resistance, ensuring longevity and requiring less maintenance even in outdoor environments.Q: What is the process of installing the clamps on rail mounting assemblies?

A: Installation involves placing the clamp on the rail-sleeper joint and using manual tools for mechanical fastening, making the process straightforward and efficient.Q: When is it necessary to replace these rail clamps?

A: Replacement may be necessary when there is visible wear, deformation, or loss of tensile strength due to extended operation, although the robust build and anti-rust finish extend their service life.Q: Where can these clamps be exported from and what are the payment options?

A: These rail clamps can be exported from major FOB ports in China, with flexible payment terms available to suit both domestic and international customers.Q: What makes your clamps suitable for extreme weather conditions?

A: Their forged carbon steel construction, high tensile strength, and temperature resistance up to 250C ensure reliable performance in various climates and demanding environments.

- Minimum Order Quantity

- 1 Set

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cutting machine Rail and Rack Category

24kg Rail Machines Railway

Price Range 55.00 - 75.00 USD ($) / Set

Minimum Order Quantity : 20 Sets

Features : Portable, robust, reliable performance

Shape : Straight

Material : Others, Alloy Steel

Length : Standard for 24kg Rail

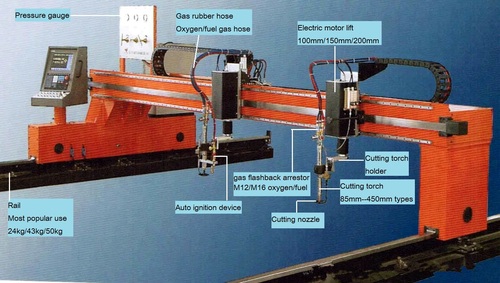

Cutting machine rail

Price Range 80.00 - 140.00 USD ($) / Piece

Minimum Order Quantity : 20 Sets, ,

Features : Corrosion Resistant, High Precision, Smooth Linear Motion

Shape : Linear Rail

Material : Others, High Carbon Steel

Length : Available from 1 meter to 6 meters

50KG RAIL CUTTING MACHINE

Minimum Order Quantity : 10 Sets

Features : Portable Durable High Efficiency

Shape : Rail Section Shape

Material : Others, HighGrade Steel

Length : Customizable Rail Lengths

RACK 25X25 GEARS RACK

Minimum Order Quantity : 1 Set

Features : Durable, corrosion resistant, precision machined

Shape : Rectangular

Material : Others, Mild steel

Length : 25 mm