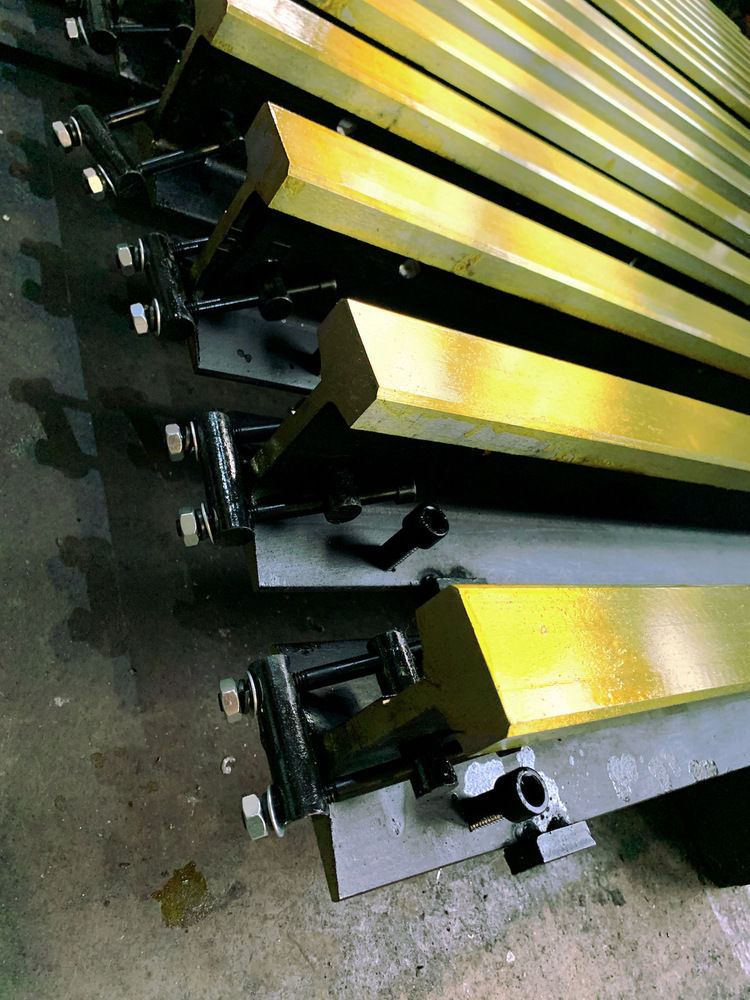

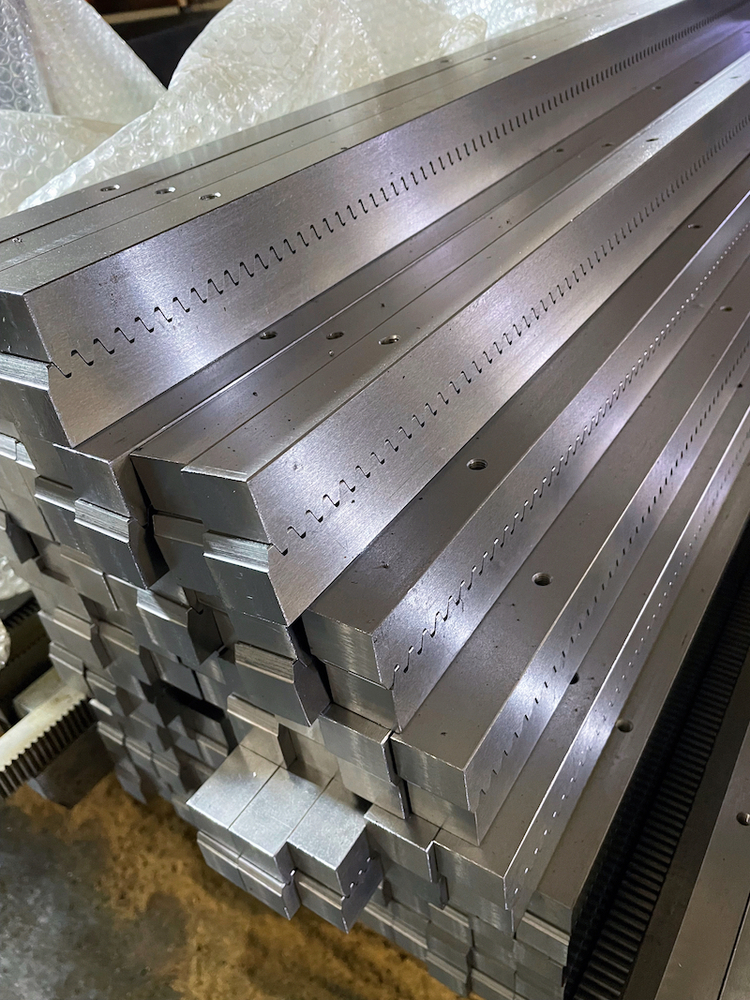

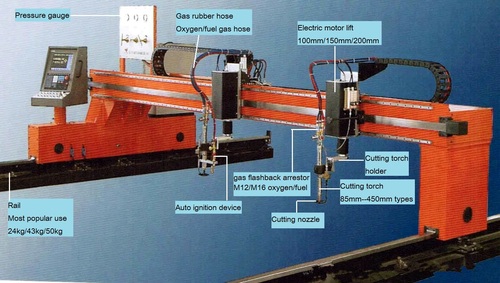

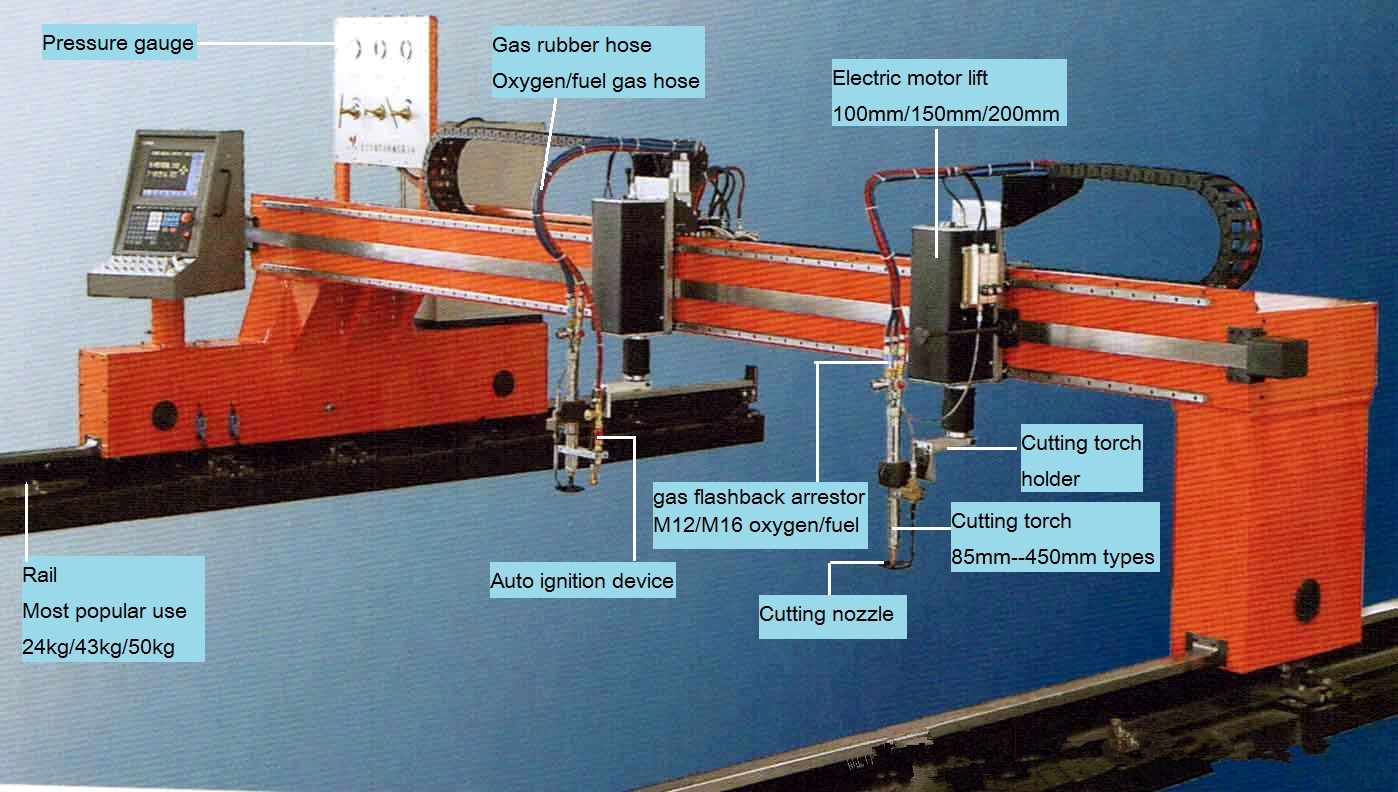

Cutting machine rail

Cutting machine rail Specification

- Shape

- Linear Rail

- Cutter Type

- Saw/Plasma/Laser Cutting Compatible

- Operate Method

- Manual / Automated

- Material

- High Carbon Steel

- Length

- Available from 1 meter to 6 meters

- Cutting Capacity

- Supports Heavy Duty Cutting Operations

- Operation Type

- Continuous/Intermittent

- Cutting Speed

- Up to 1500 mm/min (Depending on Machine)

- Cutting Force

- Machine Dependent

- Coating Type

- Oxidized / Oiled

- Tool Type

- Rail Guide / Linear Motion Guide

- Cutting Accuracy

- 0.1 mm

- Coating

- Heat Treated

- Hardness

- HRC 60 2

- Machine Type

- Cutting Machine Rail/Linear Rail

- Features

- Corrosion Resistant, High Precision, Smooth Linear Motion

- Diameter

- Applicable to Rail Cross Section (Standard sizes available)

- Maximum Torque

- As per Machine Specification

- Processing Type

- Precision Ground

- Noise Level

- Low (Below 60 dB)

- Surface Finish

- Polished/Blackened

- Maintenance

- Lubrication Required Regularly

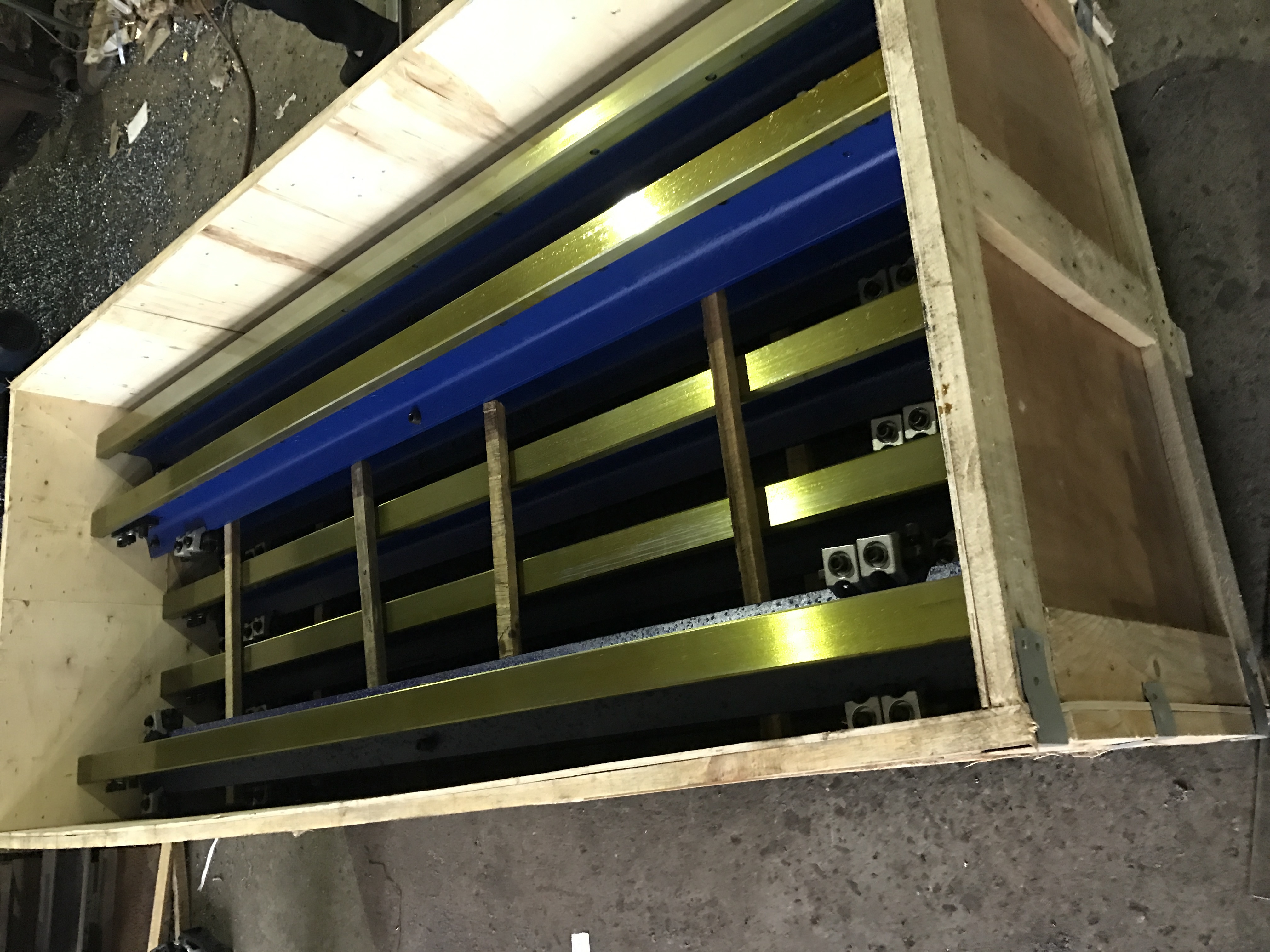

- Packing Type

- Wooden Box / As Required

- Weight

- Varies as per Size and Length

- Mounting Hole

- Counterbore/Threaded Types Available

- Working Temperature

- -20°C to 120°C

- Compatibility

- Fits Most Cutting Machine Models

- Service Life

- Up to 10 Years (Under Optimal Conditions)

- Application

- Industrial Cutting, Metal Processing, CNC Machinery

- Load Capacity

- Up to 12000 N

Cutting machine rail Trade Information

- Minimum Order Quantity

- 20 Sets, ,

- Supply Ability

- 30000 Sets, , Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Cutting machine rail

The Cutting machine rail is a precision-engineered component designed to enhance cutting accuracy and efficiency. Its sturdy construction ensures stability during operation, reducing vibrations for smoother cuts. The rails durable materials and precise dimensions make it suitable for various cutting applications, from woodworking to metal fabrication. With easy installation and compatibility with different cutting machines, this rail offers versatility and reliability. The streamlined design optimizes workflow, making Cutting machine rail a valuable addition to any workshop or manufacturing setting seeking high-performance cutting solutions.

Engineered for Industrial Longevity

With a service life of up to 10 years under optimal conditions, this rail is built to withstand demanding environments. Its heat-treated, polished, or blackened surface finish enhances durability and resists corrosion, ensuring reliable performance for continuous or intermittent operations.

Precision and Compatibility

Designed with high precision and cutting accuracy of 0.1 mm, the rail fits most cutting machine models. Standard sizes range from 1 meter up to 6 meters in length, providing flexibility for various applications such as saw, plasma, or laser cutting.

High Load and Smooth Motion

Supporting heavy-duty operations with a load capacity of up to 12,000 N, this linear rail ensures smooth, quiet movement. Regular lubrication maintains optimal performance, and its construction delivers low noise for worker comfort and productivity.

FAQs of Cutting machine rail:

Q: How should I maintain the cutting machine rail for maximum service life?

A: To maximize the service life, ensure regular lubrication of the rail and keep it clean from debris. Periodic inspections for wear or corrosion, especially in high-load or harsh environments, are also recommended.Q: What are the available installation methods for this rail?

A: The rail can be installed using either counterbore or threaded mounting holes, providing flexibility to match your specific machine requirements. Detailed installation instructions are included with the product.Q: When is surface finish selection important for my application?

A: Choosing between a polished or blackened finish depends on operational needs. Polished rails are suitable for environments demanding high precision and reduced friction, while blackened rails provide added corrosion resistance for harsher settings.Q: Where can this cutting machine rail be used?

A: It is ideal for use in industrial environments, specifically in metal processing plants, CNC machining centers, and cutting operations using saw, plasma, or laser cutters.Q: What are the main benefits of using this high carbon steel rail?

A: The rail offers high load capacity up to 12,000 N, exceptional cutting accuracy, corrosion resistance, and compatibility with a wide range of cutting machines. Its robust design ensures reliable, smooth linear motion and long-lasting durability.Q: How does the rail accommodate different cutting machine models?

A: With standard diameters and lengths, plus versatile mounting options, this rail is engineered to fit most modern cutting machine models, ensuring seamless integration into varied industrial setups.

- Minimum Order Quantity

- 20 Sets, ,

- Supply Ability

- 30000 Sets, , Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cutting machine Rail and Rack Category

24KG RAIL CUTTING MACHINE

Price 1 USD ($) / Set

Minimum Order Quantity : 10 Sets

Material : Others, Highstrength Steel

Length : Standard

Operation Type : Other, Cutting

Operate Method : Manual or Automatic

50KG RAIL CUTTING MACHINE

Price 1 USD ($) / Set

Minimum Order Quantity : 10 Sets

Material : Others, HighGrade Steel

Length : Customizable Rail Lengths

Operation Type : Other, Cutting and Shaping

Operate Method : Manual and Hydraulic Operation

RACK 20X25

Minimum Order Quantity : 1 Set

Material : Others, Alloy Steel

Length : 25 mm

Operation Type : Other, Manual or CNC Compatible

Operate Method : Mechanical Movement

RACK 20X20

Minimum Order Quantity : 1 Set

Material : Others, Mild Steel

Length : Customized or Standard Lengths

Operation Type : Other, Manual

Operate Method : Manual Placement