Two Tip Anti Collision Plasma Holder

Two Tip Anti Collision Plasma Holder Specification

- Features

- Dual tip for enhanced anti-collision, Robust construction, Easy installation, Suitable for various torch brands

- Operate Method

- Manual/Mechanized Mounting

- Coating Type

- Uncoated

- Cutting Force

- Suitable for Moderate to High Cutting Forces

- Material

- High Grade Steel Alloy

- Cutting Accuracy

- Improved Precision with Anti-collision Technology

- Tool Type

- Plasma Torch Accessory

- Coating

- Non-coated (Bare Metal Finish)

- Length

- Approximately 95 mm

- Cutting Speed

- Supports High-Speed Plasma Cutter Compatibility

- Cutting Capacity

- Designed to Accommodate Standard Plasma Torches

- Operation Type

- Anti-collision/Contact Sensor Mechanism

- Hardness

- High Structural Rigidity for Plasma Cutting

- Machine Type

- Plasma Cutting Machines

- Shape

- Round, Compact Body with Dual Tip Design

- Diameter

- Approx. 60 mm (External Diameter)

- Maximum Torque

- Withstands Rotational Loads during Torch Movement

- Processing Type

- CNC Machined for High Accuracy

- Compatibility

- Fits Most Industrial and CNC Plasma Torches

- Insulation

- Electrical Insulation Provided at Contact Points

- Maintenance

- Low, Replaceable Tips Available

- Current Rating

- Up to 200A Plasma Torch Compatibility

- Weight

- Approximately 450 grams

- Temperature Resistance

- Endures Plasma Environment Heat

- Blade Size

- Not Applicable (Holder for Plasma Cutting)

- Sensor Technology

- Spring-Loaded Contact Break System

- Mount Type

- Clamp-on/Universal Adapter

- Surface Finish

- Polished/Anti-Corrosive Treatment

- Application

- Prevents Torch Damage during Automated Plasma Cutting

Two Tip Anti Collision Plasma Holder Trade Information

- Minimum Order Quantity

- 1000 Sets

- FOB Port

- shanghai

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Two Tip Anti Collision Plasma Holder

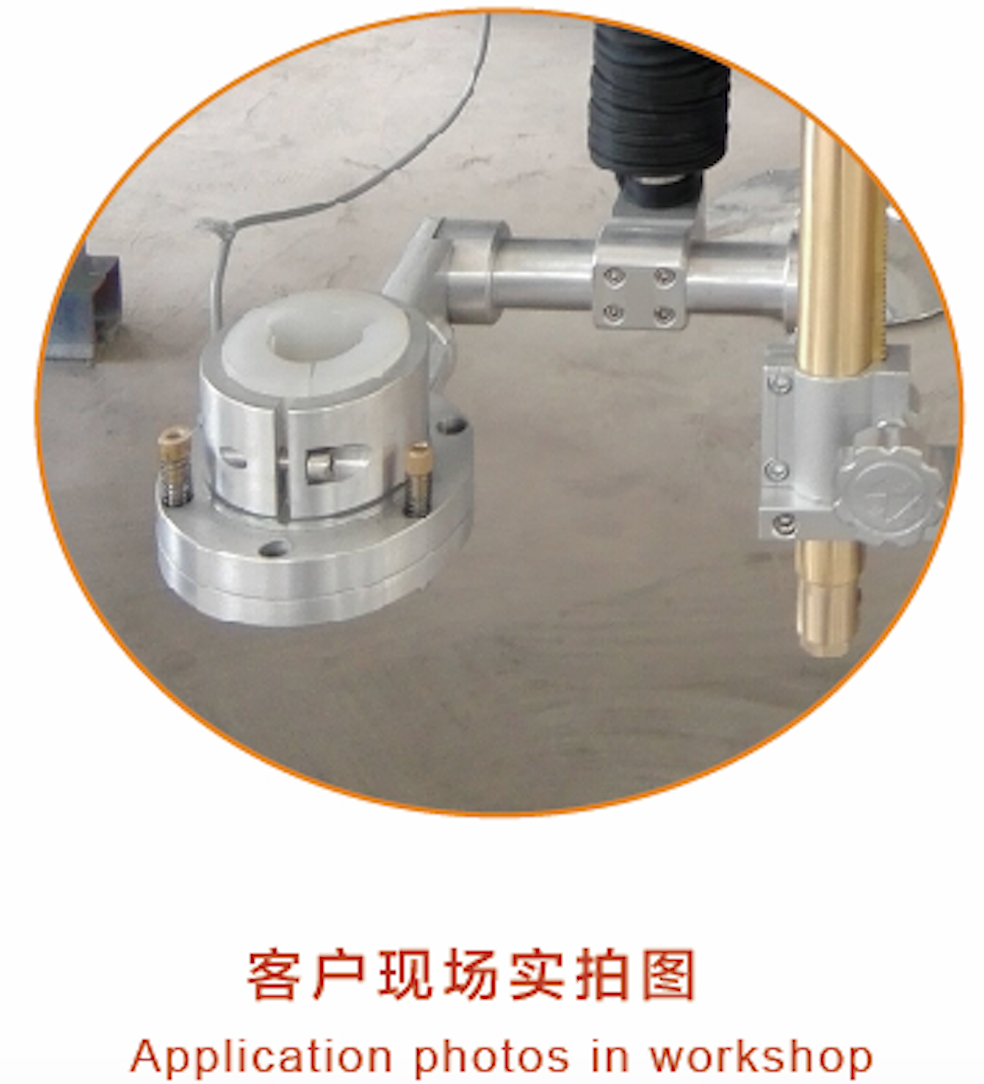

Introducing the innovative Two Tip Anti-Collision Plasma Holder, a must-have for plasma torch users. This holder is designed to prevent accidental collisions and damage during operation, ensuring a longer lifespan for your equipment. Its dual-tip design provides stable support for your plasma torch, reducing the risk of wobbling or slipping. Made from durable materials, this holder is built to withstand daily use in industrial settings. Enhance your workflow efficiency and protect your investment with the Two Tip Anti-Collision Plasma Holder.

Structural Features

- Dual-purpose torch holder designed for both plasma and flame cutting torches.

- Allows installation of plasma and flame cutting torches on the same lifting body.

- Features collision avoidance initial positioning function for plasma and angle adjustment function for flame cutting.

Advanced Anti-Collision Technology

Utilizing a spring-loaded contact break system and dual tip configuration, this plasma holder quickly detects and responds to obstructions during cutting. The contact break mechanism instantly disconnects power upon collision, shielding the torch and workpiece from damage. This allows for higher operational safety and extended equipment lifespan.

Universal Compatibility and Easy Installation

Designed with a clamp-on/universal adapter, this holder is suitable for most industrial and CNC plasma torches. Its compact round body and polished, anti-corrosive finish streamline installation onto different torch models, enabling fast setup and secure operation in challenging workshop conditions.

Enhancing Precision and Durability

With high-grade steel alloy construction and robust structural rigidity, the holder guarantees stable and accurate plasma torch guidance. The replaceable tips, electrical insulation, and resistance to harsh plasma cutting environments help ensure both precision and durabilitycritical for high-speed, high-force industrial applications.

FAQs of Two Tip Anti Collision Plasma Holder:

Q: How does the Two Tip Anti Collision Plasma Holder prevent torch damage during plasma cutting?

A: The holder uses a spring-loaded contact break sensor system and dual tip design to detect collisions with the workpiece. If an obstruction occurs, the sensor breaks contact, disconnecting power to the torch immediately and preventing physical or electrical damage to the cutting equipment.Q: What types of plasma torches are compatible with this anti collision holder?

A: This holder supports up to 200A plasma torches and features a universal, clamp-on adapter, making it compatible with most industrial and CNC plasma cutting torches from various brands.Q: When should I replace the tips of the plasma holder?

A: Tips should be replaced when you notice wear, deformation, or decreased sensitivity in collision detection. Regular inspection during routine maintenance is recommended to ensure optimal protection and performance.Q: Where can this holder be installed on my plasma cutting machine?

A: The clamp-on/universal mount design allows for installation directly on the plasma torch assembly, making it adaptable to a wide range of industrial and CNC plasma cutting machines.Q: What is the installation process for the anti-collision holder?

A: Installation is straightforward: clamp the holder onto the plasma torch using the universal adapter, ensuring electrical insulation at contact points. Secure the holder so it aligns with the torchs cutting direction and check the contact break function before operation.Q: How does using this plasma holder benefit my cutting operations?

A: By preventing torch collisions and electrical faults, the holder reduces equipment downtime, extends torch life, and increases cutting accuracy, especially during high-speed or automated plasma cutting operations.Q: Can this holder withstand the high temperatures of plasma cutting environments?

A: Yes, the holder is constructed from high-grade steel alloy with excellent heat resistance and provides electrical insulation at critical points, ensuring reliable operation even in harsh plasma environments.

- Minimum Order Quantity

- 1000 Sets

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

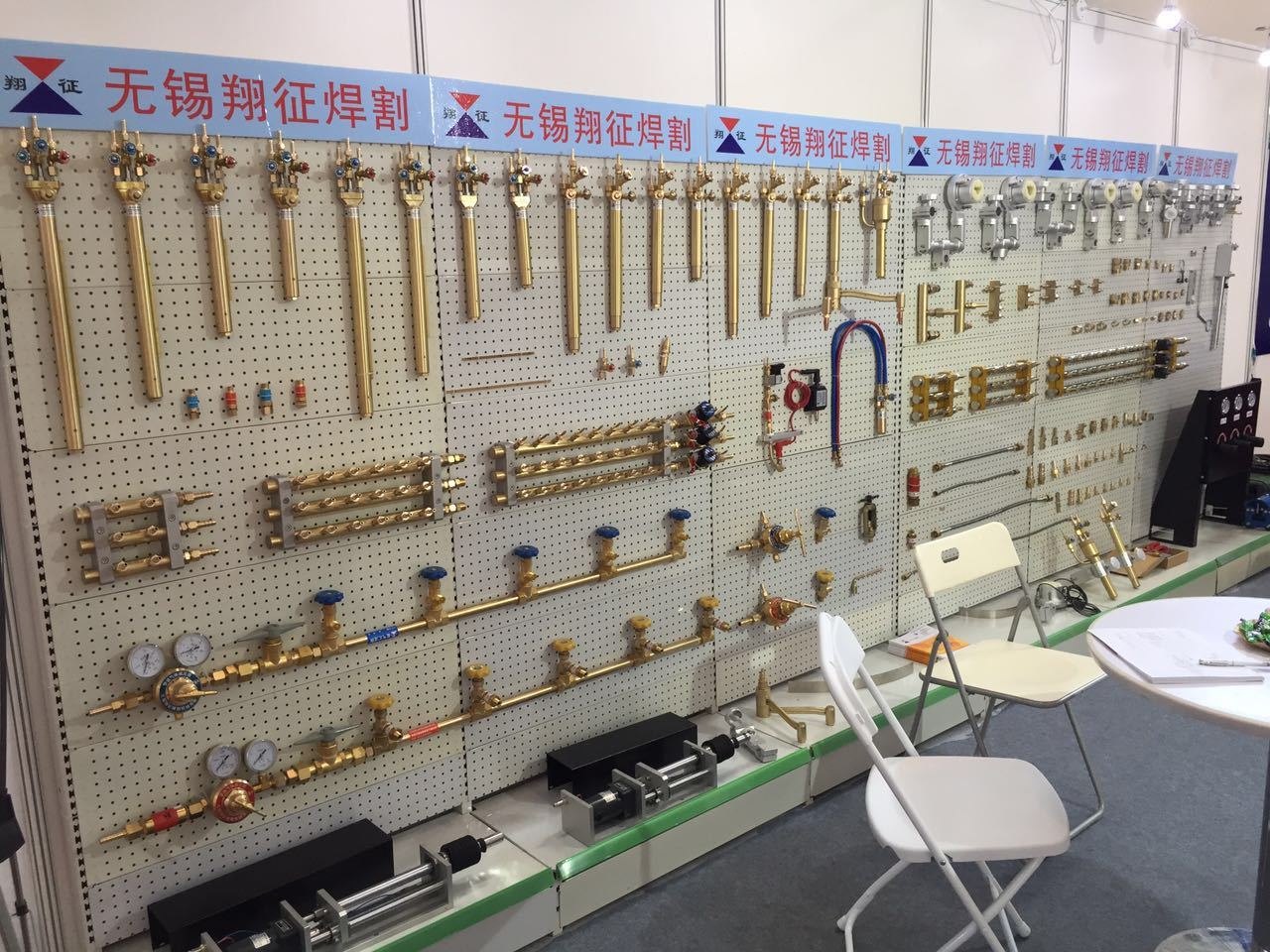

More Products in Two Tip Anti Collision Plasma Holder Category

Double use holder for marking

Minimum Order Quantity : 1 Set

Length : Approx. 120 mm (typical)

Tool Type : Hand Tool Marking

Coating : Uncoated

Hardness : High durability (for marking)

Machine Type : Nonmachine (manual tool)