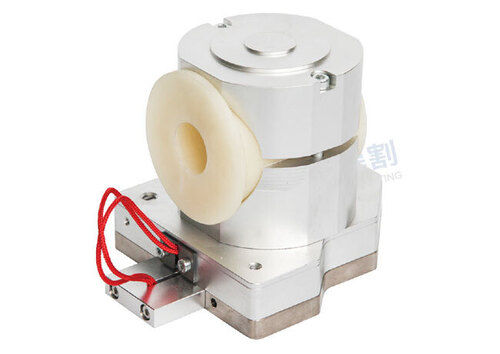

Plasma Cutting Torch Holder

Plasma Cutting Torch Holder Specification

- Material

- High Grade Steel

- Drill Bits Types

- N/A (not applicable)

- Coating

- Nickel Plated

- Cutting Force

- N/A (Holder only, cutting force determined by torch)

- Machine Type

- CNC Plasma Cutting Machine Compatible

- Tool Type

- Torch Holding Clamp

- Length

- 150 mm

- Cutting Capacity

- Up to 40 mm thickness

- Operation Type

- Manual and Automated Track Movement

- Shape

- Round Clamp Holder

- Hardness

- 58-62 HRC

- Coating Type

- Corrosion Resistant Coating

- Operate Method

- Manual Adjustment

- Cutting Speed

- Suitable for high plasma arc speeds

- Features

- Anti-slip grip, Adjustable clamp tension, Durable construction

- Cutting Accuracy

- 0.15 mm

- Diameter

- Standard 35 mm (fits common torches)

- Maximum Torque

- 20 Nm

- Processing Type

- Plasma Cutting

- Jaw Opening Range

- 20 mm to 45 mm

- Blade Size

- N/A (Holder does not include blade)

- Weight

- 520 grams

- Compatible Torch Models

- Suitable for major plasma torch brands

- Surface Finish

- Smooth Polished

- Rust Resistance

- Yes

- Application

- Holding and stabilizing plasma torches

- Mounting Type

- Side-Mount with Locking Screw

- Installation

- Tool-less quick installation and removal

- Precision Adjustment

- Fine-threaded locking knob for secure fit

- Temperature Resistance

- Up to 250°C

Plasma Cutting Torch Holder Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- shanghai

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Plasma Cutting Torch Holder

The Plasma Cutting Torch Holder is a versatile tool designed to enhance precision and efficiency in metal fabrication. Its sturdy construction ensures stability during cutting operations, reducing errors and improving the overall quality of the finished product. The holder features adjustable angles and height settings, allowing for customization based on the users preferences and specific project requirements. With its ergonomic design and durable build, this Plasma Cutting Torch Holder is an essential addition to any workshop or industrial setting, ensuring optimal performance and long-lasting reliability.

Features:

- Made from durable materials, ensuring stability and reliability during cutting operations.

- Allows users to customize cutting angles for precise and accurate results.

- Offers adjustable height settings for versatility in different cutting applications.

- Designed for comfort and ease of use, reducing operator fatigue during extended use.

Robust Side-Mount Design for CNC Operations

This plasma cutting torch holder features a secure side-mount system with a locking screw and fine-threaded knob for precise clamping. The adjustable tension and anti-slip grip ensure stable torch positioning, minimizing movement and improving cutting consistency across both manual and automated processes.

Quick and Easy Installation

Experience effortless setup and removal with the holders tool-less installation system. Simply place your torch, adjust the fine-threaded locking knob to fit (20-45 mm jaw range), and youre ready to cut. Compatibility with major torch brands makes it an ideal choice for diverse workspaces.

Engineered for Durability and High Performance

Constructed from high-grade steel and coated with a corrosion-resistant, nickel-plated finish, this holder withstands heavy use, high temperatures (up to 250C), and retains its smooth operation over time. Its robust build supports precision plasma cutting at high arc speeds, contributing to increased productivity and reduced downtime.

FAQs of Plasma Cutting Torch Holder:

Q: How do I install the plasma cutting torch holder on my CNC machine?

A: To install the holder, simply place it onto the side-mount location on your CNC machine, adjust the clamp to the appropriate jaw opening (2045 mm), and secure it with the fine-threaded locking knob. No tools are required, ensuring a quick and hassle-free installation.Q: What torch models are compatible with this holder?

A: This holder is designed to accommodate most major plasma torch brands. The adjustable round clamp with a 35 mm diameter and 2045 mm jaw opening ensures compatibility with a wide variety of standard plasma torches.Q: When should I use this torch holder in my plasma cutting process?

A: Use this holder whenever you require stable, accurate support for your plasma torchwhether operating manually or on an automated CNC track. Its secure grip minimizes torch movement, ensuring precise and consistent cuts.Q: Where can the holder be used in industrial settings?

A: This holder is ideal for use in workshops, fabrication facilities, and manufacturing plants where plasma cutting machines operate. Its robust build and rust resistance suit a range of professional environments.Q: What benefits does the nickel-plated coating and anti-slip grip provide?

A: The nickel-plated coating offers excellent corrosion resistance, prolonging the holders lifespan, while the anti-slip grip ensures the torch remains firmly in place during high-speed cutting and high-temperature operations.Q: How does the precision adjustment work?

A: The fine-threaded locking knob allows for micro-adjustments, providing a secure and tailored fit for your torch. This ensures accurate positioning with a cutting accuracy tolerance of 0.15 mm, contributing to higher-quality results.Q: What is the maximum cutting capacity and temperature resistance of the holder?

A: The holder supports cutting thicknesses up to 40 mm and is built to withstand continuous operation in environments reaching up to 250C, making it reliable for demanding plasma cutting tasks.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Cutting Torch Holder Category

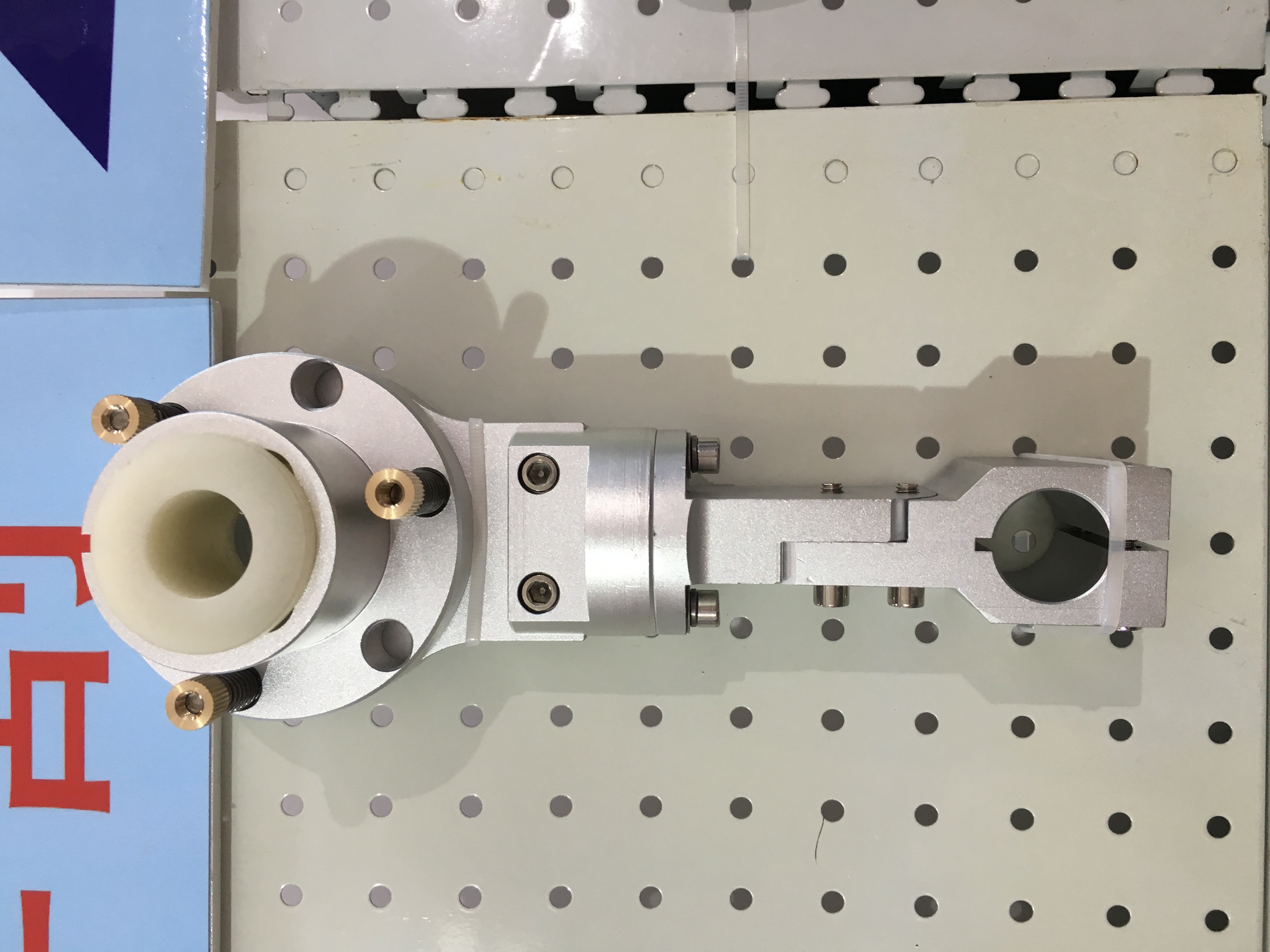

Four holes position plasma Cutting Torch Holder

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Features : Four holes for secure positioning durable construction

Tool Type : Torch Holder

Shape : Lshaped

Material : Others, Metal and Plastic

High intensity magnetic anti-collision holder

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Features : High intensity magnetic anticollision holder

Tool Type : Holder

Shape : Cylindrical with anticollision holder

Material : Others, Aluminum and magnetic components