Gear Rack

Gear Rack Specification

- Cutting Speed

- High

- Coating

- Uncoated

- Machine Type

- Gear Cutting Machine

- Tool Type

- Gear Rack

- Cutting Capacity

- Standard Duty

- Material

- Alloy Steel / Mild Steel / Carbon Steel

- Length

- Available in multiple standard/custom lengths

- Features

- Corrosion Resistant, Durable, Accurate Teeth Profile

- Shape

- Rectangular

- Operation Type

- Linear Motion

- Cutting Force

- Consistent

- Operate Method

- Manual / Mechanical

- Cutting Accuracy

- High Precision

- Cutter Type

- Gear Cutting

- Hardness

- Hardened and Ground

- Processing Type

- Machined

- Application

- Automation, Lifting Solutions, Rack and Pinion Mechanisms, Industrial Machinery

- Height

- Standard and Customizable

- Module

- Multiple options (customized as per drawing or demand)

- Mounting Type

- Bolt-On

- Teeth Type

- Straight & Helical

- Pitch Accuracy

- DIN 6/7 or As Specified

- Operating Temperature

- -10°C to 60°C

- Width

- Standard and Customizable

- Color

- Metallic Grey

- Surface Finish

- Precisely Finished, Ground Surface

Gear Rack Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets, , Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Gear Rack

The Gear Rack is a crucial component in various mechanical systems, designed to convert rotational motion into linear motion. Precision-engineered from durable materials like steel or aluminum, it ensures smooth and efficient operation. With precisely cut teeth along its length, the gear rack seamlessly meshes with gears to deliver precise movement. Ideal for applications in automation, robotics, and machinery, this Gear Rack guarantees reliable performance and longevity. Its versatile design makes it a sought-after choice for engineers and manufacturers seeking top-notch components.

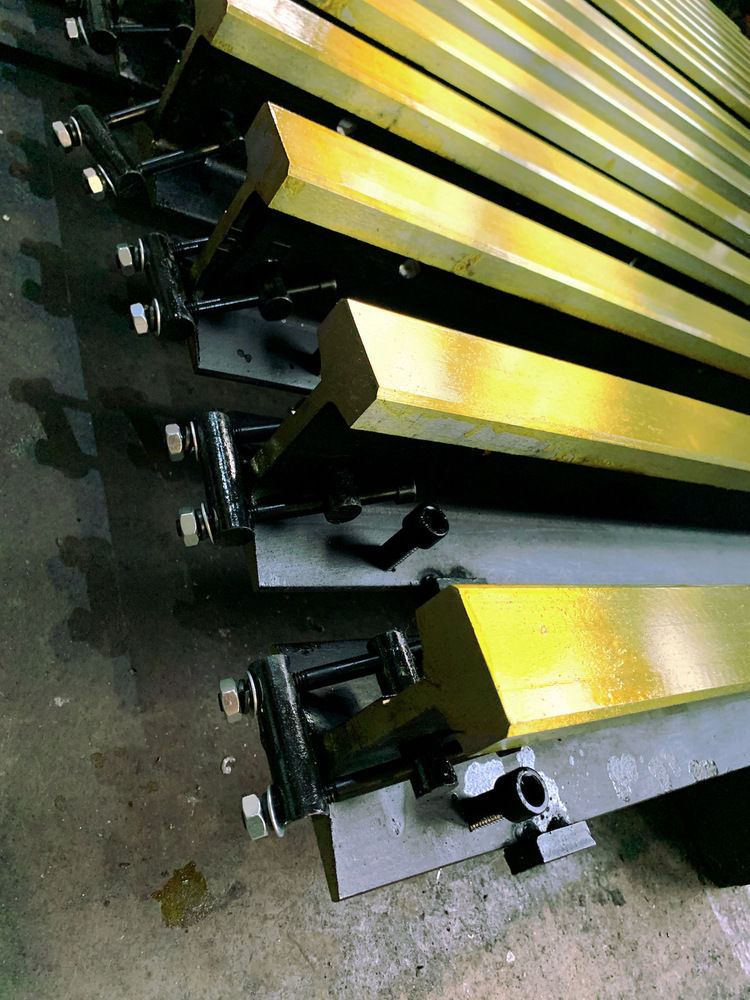

All types rack, different mould 1M 1.5M 2M 3M

Rack Spur

20x20x999mm

20x25x999mm

25x25x999mm

Rack Helical

20x20x999mm

25x25x999mm

Flexible Sizing

Gear racks are available in standard sizes as well as fully customizable dimensions to meet the unique demands of your projects. Specify width, height, length, and module to ensure a perfect fit for your automation or machinery requirements. Custom racks can be produced as per detailed drawings or specifications to guarantee precise integration.

Durable Construction

Manufactured from alloy steel, mild steel, or carbon steel, our gear racks offer excellent strength and durability. Ground and hardened surfaces help them withstand tough industrial environments and maintain high performance, even under substantial mechanical stress. The carefully engineered teeth profiles contribute to long service life and reliability.

High Performance

These gear racks are designed for superior linear motion, featuring high cutting speeds and precision. Operating temperatures range from -10C to 60C, making them suitable for various conditions. With accurate pitch per DIN 6/7 or specific requirements, they guarantee smooth, consistent motion in rack and pinion setups.

FAQs of Gear Rack:

Q: How can I customize gear rack dimensions to match my project requirements?

A: You can provide your specific width, height, length, and module preferences for a tailored gear rack. Custom options are available for both standard and specialized needs, and racks can be manufactured based on your technical drawing or unique specifications.Q: What materials are used for these gear racks, and why are they chosen?

A: Our gear racks are made from alloy steel, mild steel, or carbon steel, each selected for its excellent strength, durability, and suitability for industrial applications. These materials provide the necessary hardness and resilience for accurate, high-speed performance in challenging environments.Q: When is it appropriate to use straight versus helical gear rack teeth?

A: Straight teeth are ideal for applications where cost-effectiveness and simplicity are priorities, commonly in basic linear motion setups. Helical teeth are preferred for high-speed operations requiring quieter and smoother movement, especially in sophisticated automation systems.Q: Where are these gear racks commonly installed?

A: These racks are widely used in automation equipment, lifting solutions, rack and pinion mechanisms, and diverse industrial machinery. Their bolt-on mounting design makes installation straightforward in both new systems and retrofit projects across manufacturing, exporting, and trading operations.Q: What is the process for ordering a customized gear rack from your company?

A: To order a customized rack, provide your desired dimensions, module, material, and any technical drawings or specifications. Our engineering team will review your requirements and ensure production aligns with your applications needs, maintaining quality and pitch accuracy per DIN standards or your own specifications.Q: How does the precise finish and pitch accuracy of your gear racks benefit users?

A: A precisely ground surface and accurate pitch ensure smooth and consistent linear motion, reducing wear and optimizing mechanical efficiency. High pitch accuracy means the gear racks integrate seamlessly with pinions, decreasing maintenance and improving the reliability of your automation or machinery setup.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets, , Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

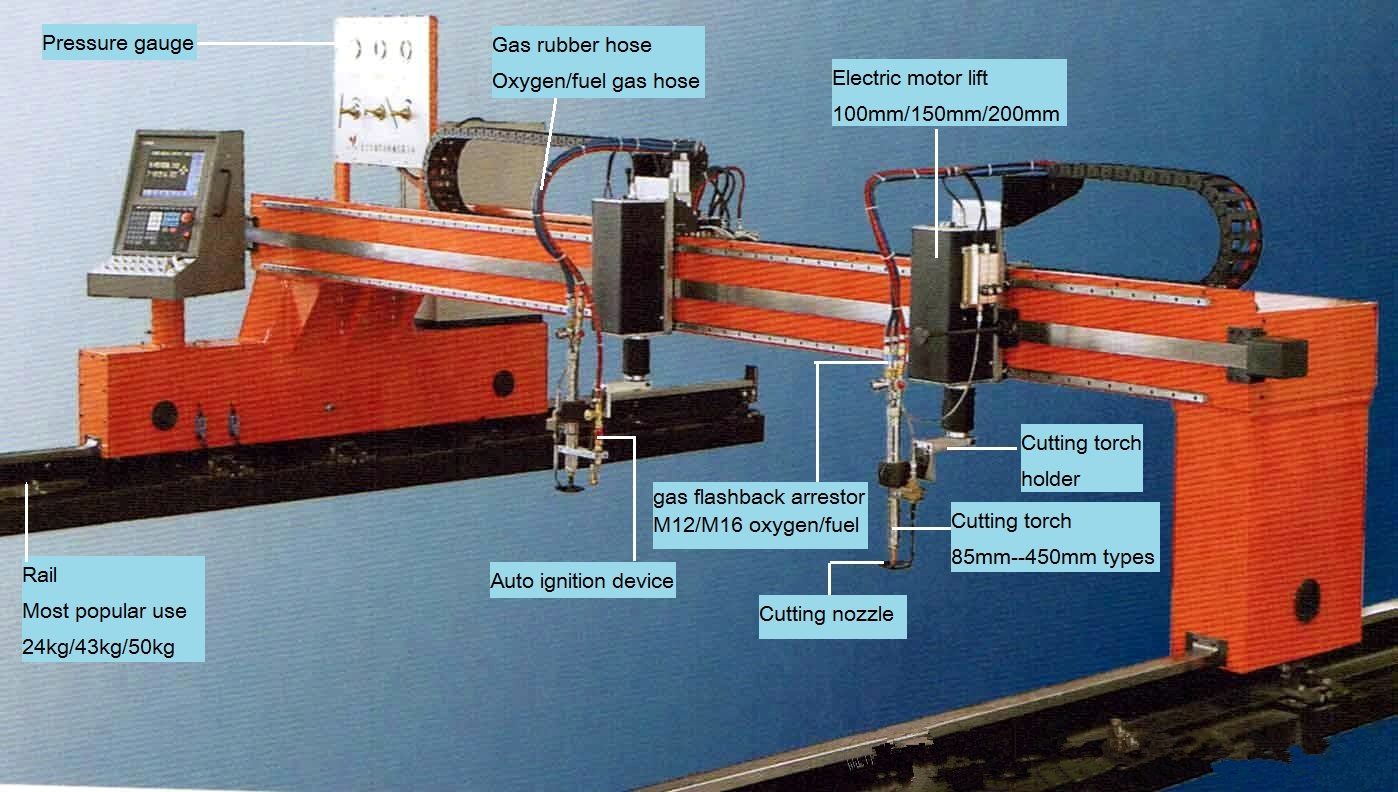

More Products in Cutting machine Rail and Rack Category

24kg Rail Machines Railway

Minimum Order Quantity : 20 Sets

Material : Others, Alloy Steel

Features : Portable, robust, reliable performance

Shape : Straight

Processing Type : Mechanical

Length : Standard for 24kg Rail

24KG RAIL CUTTING MACHINE

Minimum Order Quantity : 10 Sets

Material : Others, Highstrength Steel

Features : Portable Durable

Shape : Rectangular

Processing Type : Industrial

Length : Standard

RACK 25X25 GEARS RACK

Minimum Order Quantity : 1 Set

Material : Others, Mild steel

Features : Durable, corrosion resistant, precision machined

Shape : Rectangular

Processing Type : Gear cutting

Length : 25 mm

guide rails use in machine 24kg

Minimum Order Quantity : 1 Set

Material : Others, Alloy Steel

Features : High load capacity, Corrosion resistant, Smooth operation

Shape : Linear

Processing Type : CNC Machined

Length : Custom; Standard 1000mm