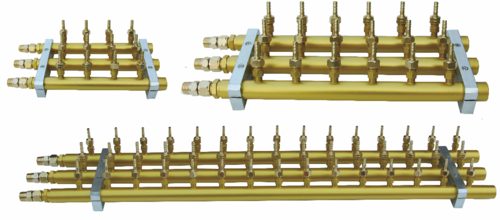

Gas Separation Panel

Gas Separation Panel Specification

- Flow Rate

- 200-2000 m/h (model dependent)

- Filtration Grade

- Fine

- Capacity

- Model specific, high throughput

- Pressure

- up to 10 Bar

- Filter Type

- Gas separation panel filter

- Media Type

- Synthetic fiber / Stainless steel mesh

- Temperature Range

- -10C to +80C

- Connecting Type

- Flanged/Threaded/Bolted as per design

- Efficiency (%)

- 98%

- Cleaning Method

- Manual or compressed air cleaning

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Fine wire mesh (customizable)

- Diameter

- Varies (customizable as per requirement)

- Construction

- Panel type, welded or bolted

- Medium Filter

- Gas

- Weight

- Approx. 20-60 kg (varies with size/model)

- Shape

- Rectangular Panel

- Feature

- Highly efficient gas separation and filtration, robust construction, easy installation

- Pressure Drop

- Initial 150 Pa

- Installation Position

- Vertical or Horizontal

- Life Span

- 2-5 years depending on operating conditions

- Frame Material

- Heavy gauge stainless steel

- Surface Treatment

- Polished/Corrosion resistant coating

- Seal Type

- EPDM gasket or silicone gasket

- Application

- Industrial gas separation, chemical plants, pharma, and clean rooms

- Port Size

- Customizable as per requirement

- Panel Thickness

- 5-25 mm (as per specification)

- Colour

- Metallic/Silver

Gas Separation Panel Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Jiangsu

- Payment Terms

- Western Union, Paypal, Telegraphic Transfer (T/T)

- Supply Ability

- 30000 Sets Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Gas Separation Panel

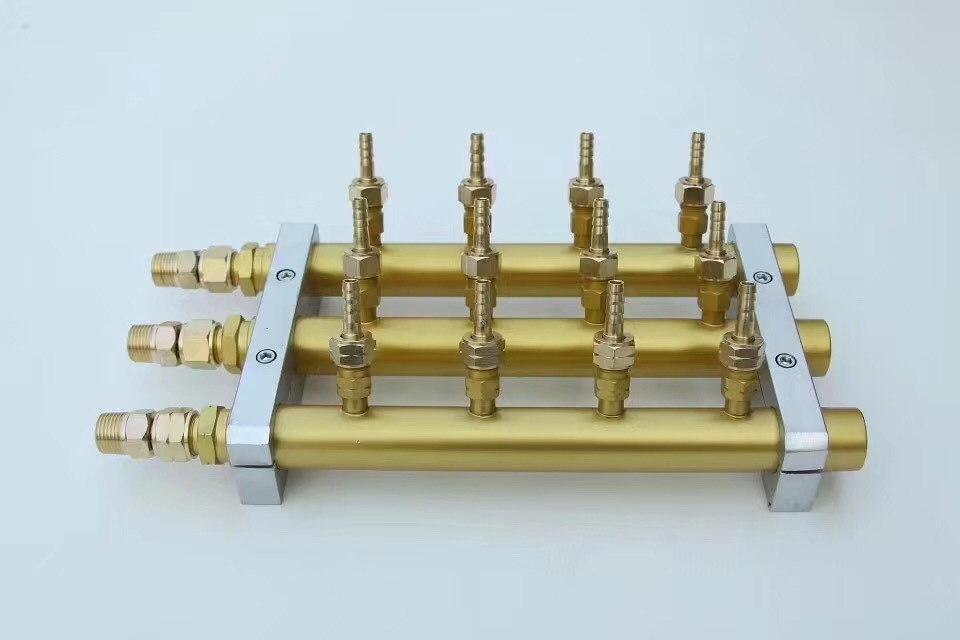

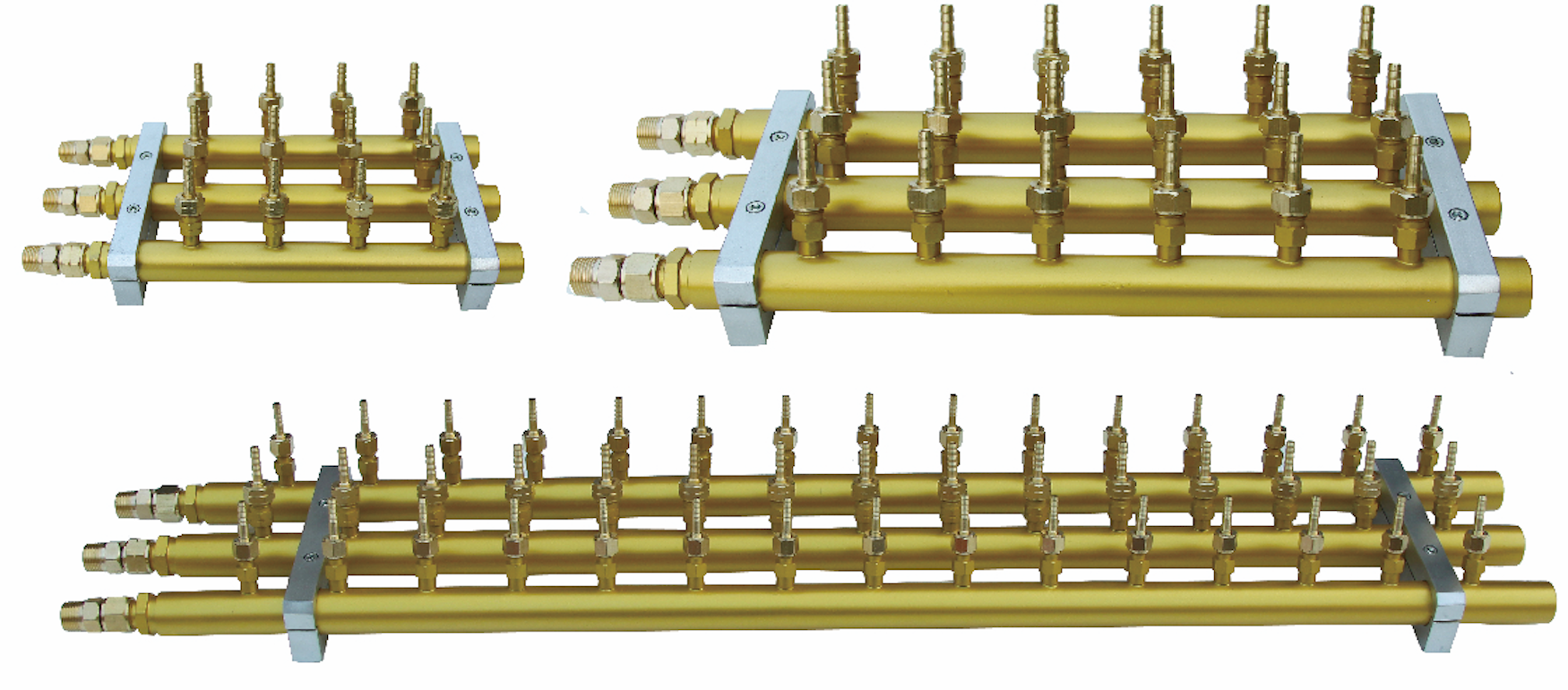

With great performance in this domain for years, we are manufacturing and supplying the superb Gas Separation Panels to our respected client for fulfilling their all demand and requirement. These are used in multi-head flame straight strip cutting machines and digital control cutting machines. Apart, also used for connecting after these parathion panel joint with the cutting blowpipe in easy and manually methods. The Gas Separation Panels are available in two different models which have smooth and dimensionally accurate fabrication and long lasting life.

Structural Features:

- With standard configuration at the gas outlet end, end-ring can be used to control the number of gas path needed.

- The number of gas separation panel groups can be customized according to customers needs.

- It adopts silver solder for the pipe system, which can effectively avoid leakage.

- It uses replaceable joint at the inlet end, which can be replaced according to customers needs.

| Model NO | Gas Service | Inlet Connection | Outlet Connection |

| FLP | Oxygen | M20X1.5-RH/M | M12X1.25/M16X1.5-RH |

| FLP | Fuel gas | M20X1.5-LH/M | M16X1.5-LH |

Robust and Versatile Construction

Each Gas Separation Panel features a rugged, welded or bolted stainless steel frame, ensuring structural integrity across a range of operating conditions. The thickness, mesh specification, and port size are fully customizable, making the panel suitable for diverse industrial gas processing requirements. A polished or corrosion-resistant coating further extends longevity and reduces maintenance needs.

Exceptional Filtration Efficiency

With a filtration efficiency of up to 98%, our panel outperforms conventional filters in demanding environments. Fine wire mesh and synthetic fiber media provide precise and effective gas-particulate separation, critical for maintaining clean process conditions in chemical plants, pharmaceutical facilities, and clean rooms.

Simple Maintenance and Flexible Installation

Designed for ease of use, the panel supports both manual and compressed air cleaning methods. Vertical or horizontal installation configurations, a range of connection types, and customizable dimensions offer seamless integration into new or existing gas filtration systems, minimizing downtime and streamlining setup.

FAQs of Gas Separation Panel:

Q: How does the Gas Separation Panel enhance gas filtration in industrial settings?

A: The Gas Separation Panel utilizes fine mesh and synthetic fiber media to efficiently remove contaminants from gas streams, achieving up to 98% filtration efficiency. Its robust stainless steel construction ensures reliable performance even under demanding operating conditions, making it ideal for chemical plants, pharmaceutical environments, and clean rooms.Q: What types of installation positions and connections are supported?

A: This panel can be installed vertically or horizontally, allowing integration into a wide variety of system layouts. Connection types, including flanged, threaded, or bolted, can be customized to meet the specific requirements of your facility or process equipment.Q: When should the panel be cleaned or maintained?

A: Cleaning intervals depend on operational conditions and the amount of particulates present in the gas stream. The panel is easy to maintaincleaning can be performed manually or using compressed air, which helps maintain peak efficiency and extends service life.Q: Where is this gas separation panel commonly installed?

A: These panels are commonly installed in gas lines within industrial facilities such as chemical plants, pharmaceutical manufacturing units, and clean rooms, where high-efficiency gas filtration is required to maintain product quality, safety, and regulatory compliance.Q: What is the process for customizing the panel to meet specific application requirements?

A: Customization is available for attributes such as panel thickness, mesh specification, port size, and frame dimensions. Clients can specify their needs during the ordering process, ensuring each panel fits seamlessly into their unique operational environment.Q: What are the main benefits of using this gas separation panel?

A: Key benefits include high filtration efficiency of up to 98%, a rugged and corrosion-resistant build, easy installation and maintenance, flexibility in installation orientation, and broad compatibility with various industrial applications. These features collectively enhance system reliability and operational efficiency.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Separation Panel Category

High and low pressure preheating Panel gas path box

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Diameter : Varies by model, typically 250500 mm

Shape : Rectangular box panel

Temperature Range : 20C to +150C

Material : Stainless Steel

Panel gas path box

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Diameter : Standard panel size (customizable)

Shape : Rectangular Panel Box

Temperature Range : 20C to 60C

Material : Stainless Steel

Metal tube XZ

Minimum Order Quantity : 1 Set

Diameter : 40 mm

Shape : Cylinder

Temperature Range : 20C to 250C

Material : Stainless Steel

Large flow pressure reducing valve XZ

Minimum Order Quantity : 1 Set

Diameter : Available in sizes DN50DN300

Shape : Globe/inline valve design

Temperature Range : Normal temperature type: 0C80C, High temperature type: up to 220C

Material : Highstrength cast iron body, corrosionresistant internal parts