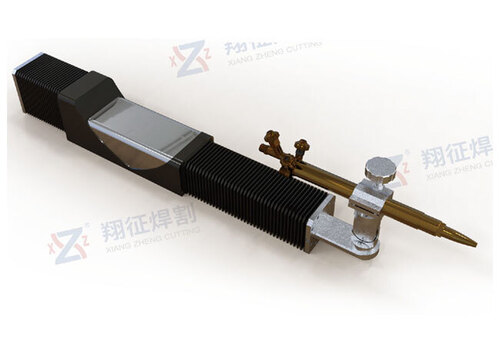

External installation of precision linear sliding table

External installation of precision linear sliding table Specification

- Material

- Alloy steel with aluminum carriage

- Hardness

- High surface hardness (tempered alloy steel components)

- Tool Type

- Linear sliding table

- Shape

- Rectangular base with linear guided rail

- Machine Type

- Motion/positioning platform

- Cutting Accuracy

- Up to 0.01 mm

- Operate Method

- Manual or automated with external actuator

- Length

- Available in various lengths (typically 100500 mm)

- Features

- High load-bearing, smooth and accurate motion, corrosion-resistant components

- Operation Type

- External Installation

- Processing Type

- Precision positioning

- Repeatability

- 0.005 mm

- Guide Rail Type

- Ball bearing or crossed roller

- Load Capacity

- Up to 50 kg

- Lubrication type

- Factory pre-lubricated

- Ambient Temperature Range

- -10C to +60C

- Application

- Automation, Manufacturing, CNC systems, Semiconductor

- Alignment

- Preset precision alignment

- Mounting

- External flange

- Protection

- Dust cover optional

- Travel Range

- Varies by model (50 mm 900 mm)

- Drive Mechanism

- Lead screw or ball screw

External installation of precision linear sliding table Trade Information

- Minimum Order Quantity

- 1 Set

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About External installation of precision linear sliding table

Versatile Applications: Precision Linear Sliding Tables

External installation linear sliding tables are widely utilized in automation, manufacturing, CNC systems, and semiconductor fabrication. These platforms offer precision positioning, making them ideal for cutting, assembly, and motion-control tasks. Their robust load capacity and high positioning accuracy suit both specific tasks requiring fine adjustments and general industrial use. With rectangular bases and linear guided rails, they are the preferred tool for optimizing efficiency in demanding technical environments.

FOB Port, Supply Ability, and Payment Options

Our precision linear sliding tables are conveniently shipped from major FOB ports in China using reliable transport services for seamless delivery. We ensure steady supply from our role as manufacturer and distributor, catering to both bulk and custom orders. Orders are processed promptly with flexible payment terms available, guaranteeing easy transactions for exporters, suppliers, and traders around the globe. This enables efficient global distribution and dependable transport services to your location.

FAQs of External installation of precision linear sliding table:

Q: How do I choose between ball bearing and crossed roller guide rails for the linear sliding table?

A: Ball bearing guide rails are suited for standard load applications requiring smooth motion, while crossed roller guide rails are ideal for higher precision and rigidity in demanding environments.Q: What is the process for installing the linear sliding table externally?

A: Installation involves mounting the sliding table using the external flange, preset precision alignment, and connecting it to your actuator for manual or automated operation. Detailed instructions are included for seamless setup.Q: Where can these linear sliding tables be effectively used?

A: They are highly effective in automation, manufacturing, CNC machining, and semiconductor processing, suitable for tasks requiring accurate positioning and repeatable motion control.Q: What benefits does the dust cover offer for this product?

A: The optional dust cover provides added protection against debris and particulates, extending the tables lifespan and maintaining performance integrity in challenging operational environments.Q: How is the linear sliding table shipped and what is the supply ability?

A: Products are shipped from China, utilizing efficient transport services. We have strong supply capabilities to handle both high-volume and custom orders promptly and reliably.Q: What is the typical use for the external installation linear sliding table in manufacturing?

A: It is primarily used for precise component positioning, cutting, and material handling, ensuring accuracy and repeatability in complex manufacturing tasks.

Price 1 USD ($)/ Set

- Minimum Order Quantity

- 1 Set

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Motor Lifter Category

Fine plasma lifter

Minimum Order Quantity : 1 Set

Tool Type : Fine Plasma Lifter

Material : Others, High Grade Stainless Steel & Industrial Alloys

Shape : Rectangular / Customized

Length : Customizable, based on application

Gantry lifter

Minimum Order Quantity : 1 Set

Tool Type : Lifter/hoist equipment

Material : Others, Mild steel / heavyduty steel

Shape : Rectangular gantry structure

Length : Customizable as per requirement

Electric Motor Lifter 200

Minimum Order Quantity : 1 Set

Tool Type : Electric Motor Lifter

Material : Others, Mild Steel/Alloy Steel Structure

Shape : Rectangular Platform with Vertical Lifting Structure

Length : Approx 1.2 to 1.5 meters (platform length, estimated)

Portable lifter

Minimum Order Quantity : 1 Set

Tool Type : Portable Lifter

Material : Others, Mild Steel / Steel Alloy

Shape : Rectangular Platform with Vertical Beam

Length : Approx. 1.2 to 1.5 meters or Customized