Cable Pulley

Cable Pulley Specification

- Lifting Height

- 6 meter

- Application

- Wire Rope and Cable Lifting

- Chain Length

- 2 meter

- Pulley Type

- Cable Pulley

- Load Capacity

- 500 kg

- Power Source

- Manual

- Number Of Grooves

- 1

- Mounting Type

- Hanger Mount

- Sling Type

- Single

- Bore

- 20 mm

- Diameter

- 100 mm

- Bearing Type

- Ball Bearing

- Features

- Corrosion Resistant, Heavy Duty Construction

- Material

- Mild Steel

- Sheave Material

- Steel

- Color

- Black & Silver

- Wheel Thickness

- 12 mm

- Surface Finish

- Powder Coated

- Weight

- 2.5 kg

- Suitable Rope Diameter

- 8-12 mm

- Operating Temperature Range

- -20°C to +60°C

Cable Pulley Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- shanghai

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Cable Pulley

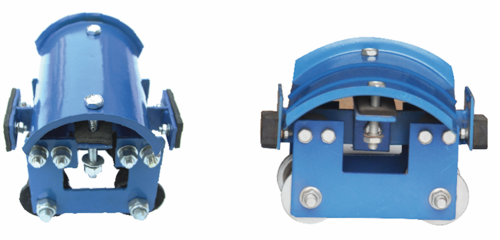

We, WUXI XIANG ZHENG CUTTTING & WELDING MACHINERY CO.,LTD is engaged in providing the effective Cable Pulley. It is installed and fixed in the gas tube of flame cutting machine, cable, power cord of planer automatic welding machine and cable of submerged arc welding machine etc. Apart of this, several pulley or gas assembled on the positioned 10 1-beam steel. The machine runs straight due to the Cable Pulley or gas tube which tend to be moved on the I-beam steel along with the pulley. As a result, the machine will not be interfered by power cord or gas tube while working.

Features:

- Ideal for securing gas pipes, cable lines, power lines for gantry automatic welding machines, and cable lines for submerged arc welding machines in flame cutting machines.

- Equipped with multiple cable pulleys assembled on a 10 # I-beam for seamless movement of cables or gas pipes along the I-beam during straight-line machine operations.

- Ensures convenient operation and remains unaffected by cable and gas pipe interference, enhancing overall work efficiency.

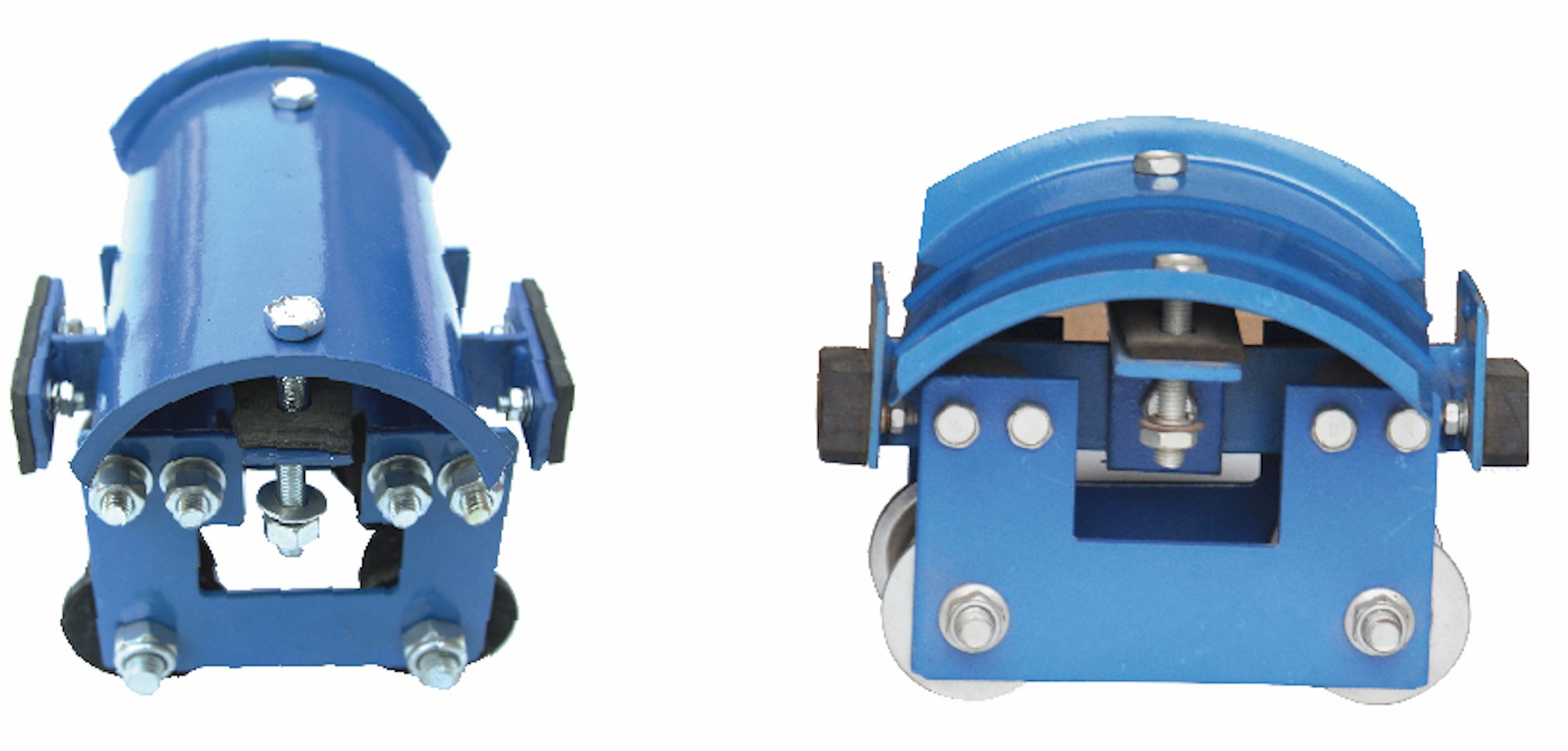

Corrosion-Resistant and Heavy Duty

Featuring a premium powder-coated surface and constructed from quality mild steel, this cable pulley delivers outstanding resistance to corrosion and wear. Its heavy-duty build ensures long operational life, even in challenging conditions. The system is well-suited for consistent, reliable performance in environments where durability is crucial.

Designed for Efficiency and Safety

Equipped with ball bearings and a single groove sheave, the pulley ensures smooth and efficient lifting of wire ropes or cables up to 12 mm in diameter. Its secure hanger mount and manual operation provide enhanced control and safety, making it suitable for various industrial lifting operations.

FAQs of Cable Pulley:

Q: How do I install and operate the cable pulley?

A: To install, securely mount the cable pulley using the hanger mount at the designated location. Pass the suitable rope (812 mm diameter) through the sheave. Since it is manually powered, simply pull the rope to lift or lower loads within the 6-meter lifting height. Ensure all connections are secure before use.Q: What materials are used in the construction of this cable pulley?

A: The cable pulley is made primarily of mild steel, with a steel sheave. The surface is finished with black and silver powder coating to enhance corrosion resistance and longevity.Q: When should this cable pulley be used?

A: This pulley is ideal for heavy-duty lifting tasks in industrial and construction environments. Use it for wire rope and cable lifting functions where robust performance and durability are required, within its 500 kg load capacity and -20C to +60C operating temperature range.Q: Where is this cable pulley most commonly utilized?

A: This cable pulley is widely used in factories, warehouses, construction sites, and workshops where manual cable and wire rope lifting is needed, especially in scenarios demanding reliability and resistance to harsh conditions.Q: What is the benefit of the powder-coated finish?

A: The powder-coated finish provides a tough, corrosion-resistant surface that protects the steel components from rust and environmental damage. This extends the pulleys life and maintains appearance and function through repeated use.Q: How does the ball bearing improve the pulleys performance?

A: Ball bearings reduce friction and ensure smooth rotation of the sheave, making manual lifting of heavy loads easier and more efficient while also minimizing wear on the pulley components.Q: What is the process for selecting the appropriate rope for this pulley?

A: Select a wire rope or cable with a diameter between 8 mm and 12 mm to match the groove of the pulley. Ensure the ropes strength is sufficient for your load, not exceeding the 500 kg capacity.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30000 Sets Per Month

- Delivery Time

- 3-7 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Pulley Category

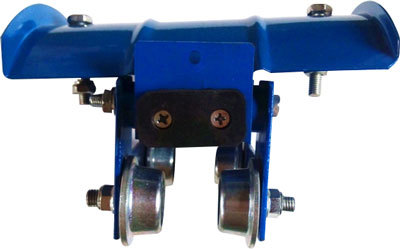

Cable Pulley XZ

Minimum Order Quantity : 1 Set

Features : Durable corrosionresistant smooth operation

Material : Highstrength steel, Other

Bearing Type : Ball bearing

Diameter : Customizable upon requirement

Bore : Other, Standard bore